DECEMBER 2022

Wood Thread

Cutting with a

Screw Box

and

Tap

with Paul

Reeves.

Thu 15th

Dec 2022 at MWCC Club Night

(click any photos in this

demo for close up views)

You will need a matching set of Screw Box and Tap.

A size suitable for cracking nuts would be about ¾" diameter.

A close grain wood would seem a better choice but Paul has had mixed results

when tapping into hard wood end-grains as the resulting threads would often

crumble away.

He found that threads were more sturdy when cutting across grain for hard woods.

TOP TIP

: If using soft wood, tap

into the end grain after allowing some thin supaglue to soak into it. This will

stabilize the resulting action of the cutter as it produces a thread.

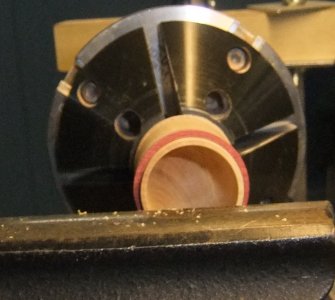

Making a Nutcracker

The Body

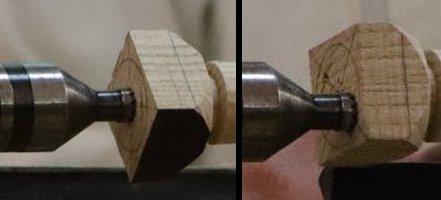

For the demonstration Paul had prepared

a 3" square by some 6 to 7" length of Hornbeam to mount into a chuck.

The width of the holding bowl will depend upon which nuts you are intending to

use : small nuts like almonds/hazel nuts would need about 1" diameter whereas

larger nuts like walnuts would need more room. (Probably best not build one for

a Coconut!)

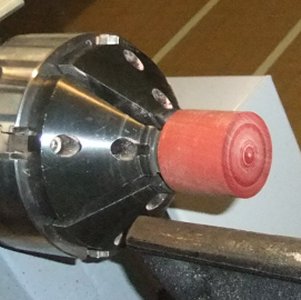

In order to accommodate walnuts, Paul fixed an 1¼" diameter Forstner bit into a

Jacobs Chuck held in the tailstock marked for a depth of about 2" - this would

allow the walnut to be inside enough to be held steady rather than catapulting

out the opening when applying pressure with the screw crusher.

With the bowl hollowed, the Forstner was removed.

A hole in the side was drilled with a size slightly less than the Tap's

diameter. (If you study the photo above for the ¾" Screw Box, you will

notice Paul's Father had placed a ⅝" flat

hole cutting tool as a starting point but Paul chooses to use a slightly larger

Forstner)

The Tap is going to form the female thread. Once the Tap has started a thread,

it will need to be reversed a quarter of a turn after about every half turn in

order to clear the cutting debris.

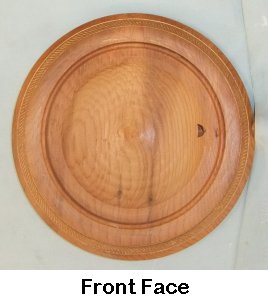

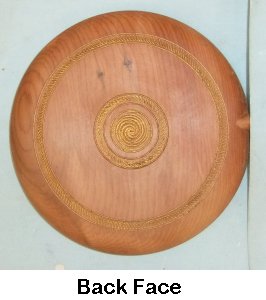

With the thread completed, the outside was turned and shaped into a barrel with

the thread hole at the fattest dimension.

TOP TIP :

When your gouge passes over the thread hole, you will

need to avoid any excess weight into the wood or else you will end up with a

dent/cove in line with the hole.

Keep a check where the bottom of the hollowed bowl is relative to the outside in

order to avoid shaping the handle too close and weakening the piece.

Abrasives were used through the grits but again, being careful of around the

thread hole or else it would end up elongated. The first grit has to rid the

scratches left by the gouge, while the finer grits get rid of the previous

abrasive marks.

The piece was turned around and a Jam Chuck was used to drive via the Forstner

hole.

The original spigot was turned away to a thin support, but strong enough to

maintain the piece against the Jam Chuck. The thin support was sawn off and

abrasives applied to finish.

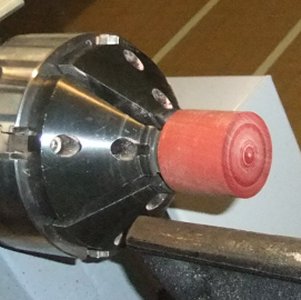

The Crusher

A square blank of Hornbeam about 8" long was mounted between centres and turned

to a cylinder at the required diameter for the chosen Screw Box size.

The length of thread required on the dowel was measured from the outer edge of

the bowl though the thread hole to the opposite inside edge. A further 1" was

added to compensate for the distance the dowel has to go into the Screw Box to

reach the thread cutter, which creates the male thread, and for the space of a

chamfer to be turned at the end point of the thread (to help avoid damaging the

thread as it contacts the nut or else the curved inner surface of the bowl).

This is best achieved accurately by use of a Skew Chisel held with the long

point down.

Unlike the Tap procedure, the Screw Box

technique requires turning the dowel in the same direction (without any quarter

turns in reverse) so that the off cut exits the box without breaking off and

jamming inside.

A handle was then turned and sanded before being sawn off at the chamfered

bottom of the thread and at the top of the handle.

TOP TIP :

If using softer woods, a hard tip could be added to the

bottom of the thread with a hob nail or gluing a button of hard wood, eg Box,

Rosewood etc.

(photos by Rick

Patrick & Paul Reeves)

<to

index>

October 2022 -

DEMO

4

Animals

with

Paul Reeves

Thu 20th Oct at MWCC Club Night

The Internet can show a confusing scrapbook of

examples but googling, for example, "animals for wood turners" should be able to

give you more focused ideas.

The challenge to produce something unique is to see a picture of a finished item

and then use your experience and wits to work out how to achieve it rather than

just following instructions from start to finish.

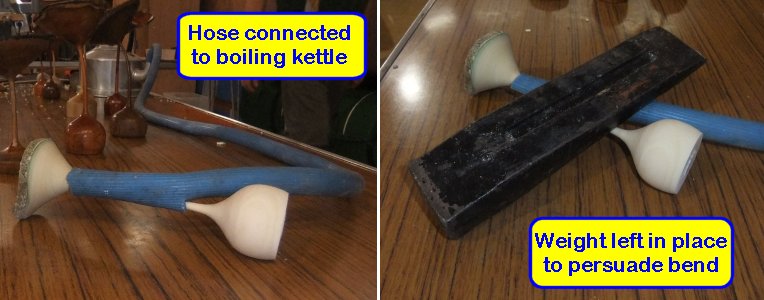

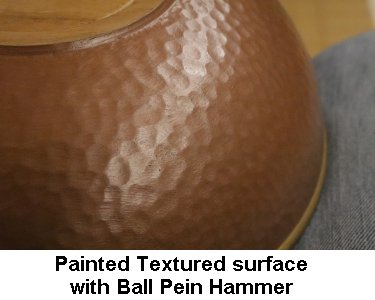

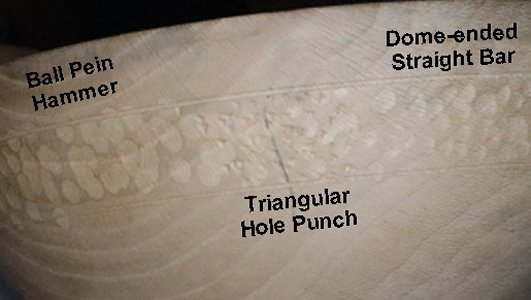

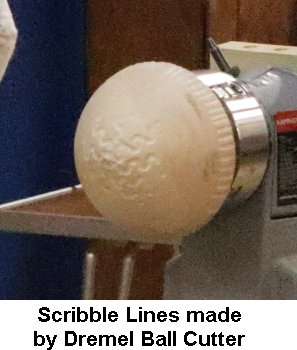

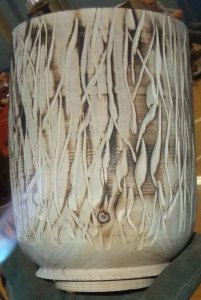

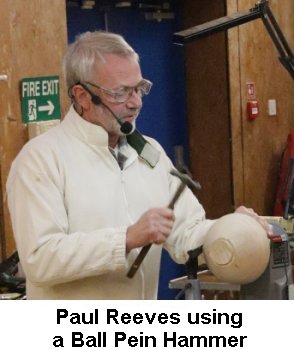

Paul had seen a picture of a hedgehog and thought he could improve it with an

up-turned snout using 'Off Centred Turning' principles and some 'Texturing' to

suggest a prickly coat.

(You can find both of these techniques described in our previous demonstrations

<HERE>)

When approaching a project where you have to work out the way of doing things,

it is likely that you will need to experiment on your first attempt. Paul

confided that the finished article he had shown at the start was his second

attempt and that he had adapted it from his initial plan.

HEDGEHOG

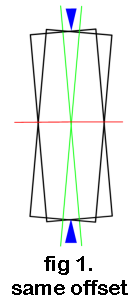

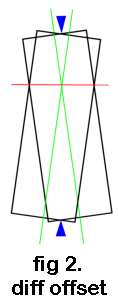

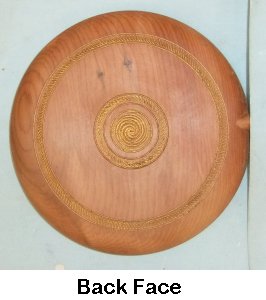

He

didn't need a big piece of wood - he had selected a 100mm length of 40mm square

and marked diagonals on both ends. To achieve the eccentrical turning to come,

he marked the centre and a small offset up one diagonal with a larger offset on

the other side of the centre mark. He repeated this at the other end taking care

to mark the same offsets adjacent to the same side edge.

He

didn't need a big piece of wood - he had selected a 100mm length of 40mm square

and marked diagonals on both ends. To achieve the eccentrical turning to come,

he marked the centre and a small offset up one diagonal with a larger offset on

the other side of the centre mark. He repeated this at the other end taking care

to mark the same offsets adjacent to the same side edge.

The large offset would be used for the animal's underneath and one of the small

offsets would be used to form the face.

The Body

With the blank mounted between centres, Paul turned it to a cylinder

and then marked out the desired length of the hedgehog while ensuring that each

end had sufficient remaining wood to be strong enough to support the head and

tail drives for subsequent texturing and offset turning. He rounded off the back

end of the animal (without parting off) and tapered the face end.

It was important to sand before texturing because it would be impossible to sand

anything afterwards without spoiling the texture effect.

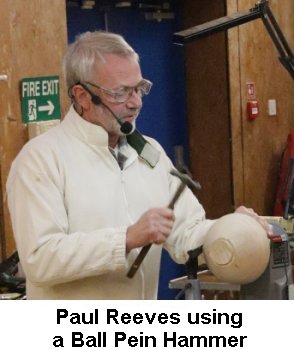

Paul's texturing tool was a

metal-worker's Knurling Tool (although similar could be achieved with others

available eg Henry Taylor Decorating Elf). To obtain the best result, Paul

maintained a positive inward force to keep an even pressure on the cutting

wheel(s) while the tool was moved along the tool rest making contact parallel to

the surface of the piece.

Paul finished the body with some appropriately coloured stain applied with a

cloth.

The Underneath

With the blank now centred on both large offsets AND checking by hand-turning

before starting that the piece cleared the tool rest, Paul started turning away

the hedgehog's underneath. This called for smooth movements because of the the

intermittent contact of the cutting edge of the gouge. The back and front ends

were rounded away but importantly, NOT turned away more than the central axis of

the starting cylinder (which of course is not the same as the central axis of

this current configuration). Paul's intention was to get the end of the finished

nose at the original central axis.

The underneath was then sanded with abrasives on a hard flat block held rigidly

perpendicular to the turning surface such that it only sanded the newly turned

surface without affecting the edge of the textured surface.

The

Face

The piece was configured with the headstock driving the central spot and the

tailstock holding the small offset at the hedgehog's face end. Paul turned away

the cylindrical wooden block end carefully so as to preserve the original

cylinder's central spot, which allowed better access to turn away a curved face.

This was sanded with a flat block as above before reconfiguring both stocks to

the original centres.

The tail and snout ends were turned away to almost parted. A Skew was the

preferred gouge to finish off the cross-grain ends to thin stubs, which were

then sawn clear.

The new cuts were tidied up with abrasives and fresh coloured stain applied to

the tail end.

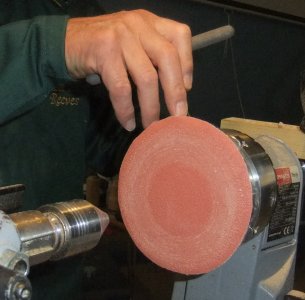

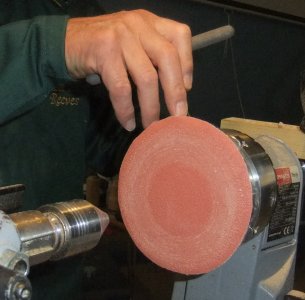

Paul set the headstock with a block holding an abrasive disc with Velcro in

order to put a flat on the underside to aid stability.

-----o00000o-----

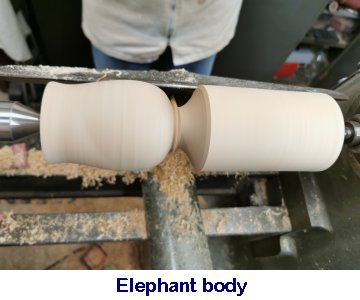

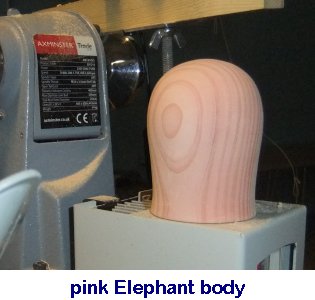

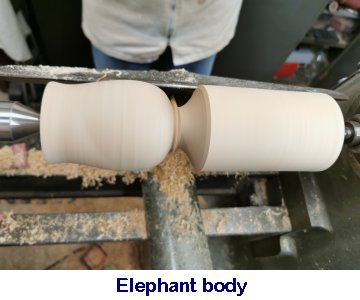

ELEPHANT

Another turned animal that caught Paul's attention was an Elephant, but very

much in a Scandinavian style rather than life-like. The design was clearly in 4

separate pieces connected together; possibly by dowels or perhaps by gluing

flattened bearing surfaces.

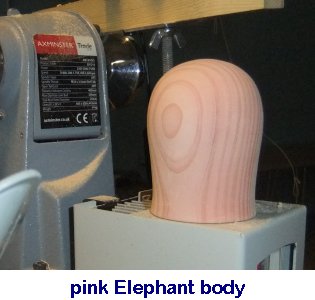

Inspired by the thought of a pink Elephant, Paul chose his recently planked

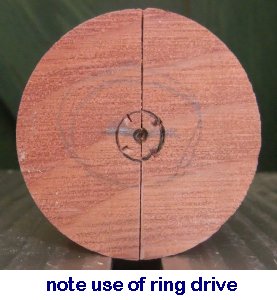

Redwood. This is a soft and slightly brittle wood so a ring centred tailstock

would be best.

The Head & Trunk

He had prepared the body prior to demonstration as it was a simple shape. Paul

felt the stylized head and trunk shouldn't touch the ground nor be much higher

than the body. He shaped and sanded before removing from the centres with a Skew

Chisel across the end-grain.

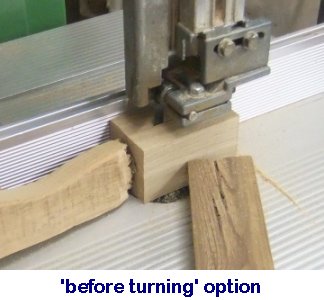

The

Ears

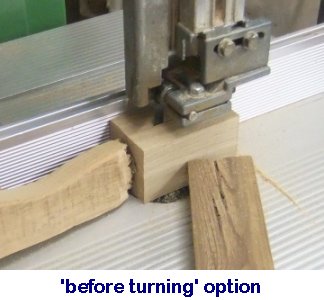

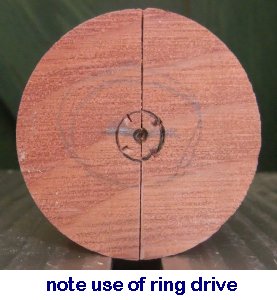

With an appropriately sized square blank, Paul had band sawed it in half and had

taped the halves together again with double-sided sticky tape applied to the

ends. (This can be done after turning but it helps to keep the ends square). Both drive and tail stocks needed to be ring centred types to avoid the

piece from splitting apart while turned to a centre. Having ridden elephants

himself while holidaying in Asia, Paul could vouchsafe that their ears were

quite triangular so he turned the cylinder into an oval shape before sanding and

then removing from the blank using a Skew. This resulted, after separating, into

a rounded triangular shape.

For assembly, he carefully checked

where the various components would need to be joined so he could then sand flat the

corresponding surfaces using the circular Velcro-holding disc above ready to be

hot glued together.

The November Competition was set for a

turned example of an animal as a stand alone piece

or

else on / in something relevant.

<Competition Results>

(photos by Andy Ogilvie, Rick

Patrick & Paul Reeves)

<to

index>

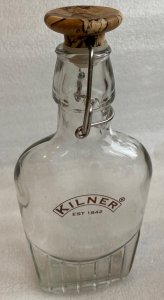

SEPTEMBER 2022

Taking on the

Kilner Challenge with

Andy

Ogilvie

Thu 15th

Sept at MWCC Club Night

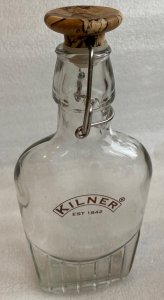

As an enthusiast of being given a challenge rather than following someone else's

'recipe' of turning procedures, Andy accepted the 'Kilner Challenge' :-

To create an air-tight container like the renown Kilner Jar.

Following the standard plan of "Research -Theory - Practice - Refine," it looked

like he might fall at the first fence!

No amount of Google searching revealed anybody, anywhere able to supply the wire

hinges used by Kilner.

Neither could he devise a curved, hinged alternative made of wood; so his only

alternative was to cannibalize the wire hinge contraptions from an old Kilner

jar.

The closest he could find was that Asda had medium jars and clip top spice jars

on offer for £1.20 (as of Sept 2022).

It turned out that this was helpful as it became clear that whatever size of

hinge he used, it could not be adapted nor adjusted. Consequently, precise

dimensions at the bottom of the lid and at the top of the jar were required for

them to come together parallel and have any chance of the finished item being

air-tight.

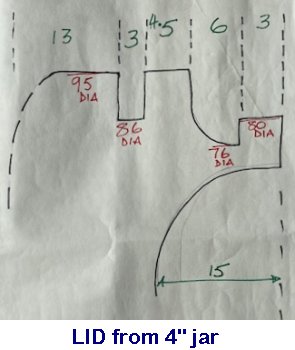

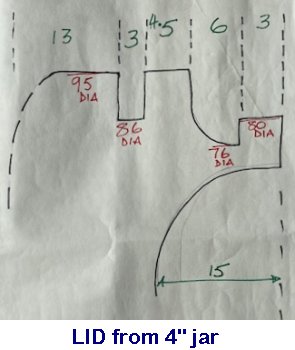

Before Andy started off turning wood, he prepared drawings showing all the

crucial distances & circumferences between the wires when closed, from accurate

measurements of his wire hinges 'stolen' from a 4" diameter jar.

These drawings were set and orientated correctly in his line of view from in

front of the lathe.

Andy had turned a lid and a base at home and found ways to refine the design

which he would highlight at the end of the demonstration.

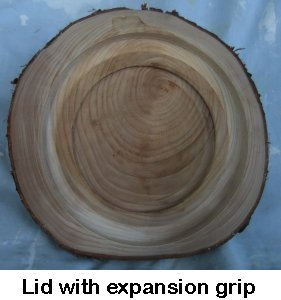

Turning a Lid

Andy had prepared a 4" square blank of Ash mounted in jaws and turned it down to a

95mm cylinder.

Working from his drawing and using an Outside Spring Caliper, Andy carefully

reduced the end 9mm to an 80mm diameter cylinder. (This could be achieved with

Parting Tool / Spindle Gouge / Skew - whichever preferred)

Using a thin Parting Tool and the Caliper, he turned a notch to a 76mm diameter,

which matched the internal diameter of the rubber seal (also cannibalized from

the Kilner Jar). This was subsequently turned back to the 95mm diameter as per

his drawing.

Similarly, a 3mm notch with a wider Parting Tool was turned to an 86mm diameter

at 11mm above the previous notch to accommodate the wire frame for the lid.

Next, the bottom of the lid was hollowed out while keeping in mind to keep the

resulting wall thickness strong enough to withstand any forces from the wire and

seal.

An appropriate groove was cut inside this hollowing to suit his chuck jaws in

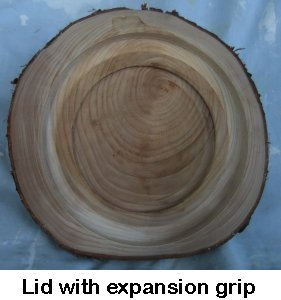

expansion, which would be needed to reverse chuck the lid.

Finally, the top of the lid was rough shaped WITHOUT parting off.

The sides, notches & hollow were carefully sanded to crisp edges before reverse

chucking and finishing the lid top with gouge and abrasives.

The wire for the lid can be separated at the hinge and its loop be expanded over

the side of the lid before engaging the appropriate slot and re-engaged with the

hinge. Similarly, the rubber seal was fitted into its notch.

Turning a Base

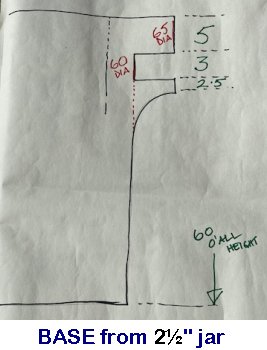

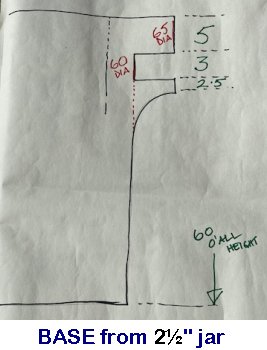

This time,

Andy

used the seal and wire hinge from a 2½" jar for his demonstration.

He

had prepared another drawing and a blank of Ash turned to a cylinder of 65mm and

with enough length to exceed 60cm depth of vessel.

The base was turned with the diameters, grooves, shaping and hollowing with

regular check-fitting of the base with its matching lid (turned prior to this

evening to save time) using the same method as described above for 'Turning a

Lid'.

The thickness of the walls at the base opening is most critical for strength at

its narrowest point (ie where the wire hinge sits.

Reverse chucking, shaping, detailing

and sanding carefully were completed as above.

Some thought should be given to which type of

finishing to use.

As the most common contents of these jars will be foodstuffs, a 'food safe' oil

or wax should be considered for at least the inside surfaces.

Refinements

Andy explained that his first wooden lid & base attempt for a single jar was

a design he subsequently rejected because it prevented the user to visually

identify the contents, whereas a glass jar is obviously not as limited.

However, adding wooden lids to glass bases or wooden bases to glass lids

overcomes this limitation and certainly enhances their style.

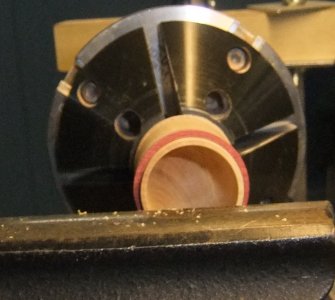

Another possible enhancement was by adding a

flower decoration, which Andy demonstrated after the tea break using Box with a

Purpleheart insert (shown above).

Finally, Andy produced a wooden top version for a Kilner bottle that he had made

at home to complete the Kilner range as well as his Challenge for the night.

<to

index>

August 2022 -

DEMO

3

Puzzles

& Tricks with

Paul Reeves

Thu 18th Aug 22 at MWCC Club Night

For clarity, games like Solitaire (although they

involve many turned parts) are not considered a puzzle in the sense we mean

tonight.

We are looking for a teaser that cannot be easily or readily solved.

For example, Paul's Ball & Beehive puzzle with its apparently disappearing ball,

is a precisely turned piece with a very thin walled half ball within a segment

of a model skep (ancient straw beehive).

Lipstick Puzzle

The Puzzle Maker demonstrates to his

punter that the inner lipstick is able to slip out of its tube by turning it

upside down.

The task is to remove the inner lipstick without tipping it over. The stick is

annoyingly smooth, pointed and barely above the rim of the outer box.

The skills required of the woodturner are to fashion the lipstick to a close fit

of a perfectly parallel inside wall of a box and at just the right height to be

unable to grip with fingertips. Also, as a contrast of colours appears more

striking, choose woods that have stood long enough to have stabilized their

moisture content and are of varieties unlikely to shrink/swell differently to

each other on dry/wet days.

The skills required of the woodturner are to fashion the lipstick to a close fit

of a perfectly parallel inside wall of a box and at just the right height to be

unable to grip with fingertips. Also, as a contrast of colours appears more

striking, choose woods that have stood long enough to have stabilized their

moisture content and are of varieties unlikely to shrink/swell differently to

each other on dry/wet days.

The best way to achieve the parallel wall is by using a drill held within a

Jacobs Chuck in your tailstock, (although if you don't have these tools

available, next best is a Box Cutter).

As accuracy of this cut is paramount and there can be a tendency for a drill to

'walk' on its first touch, you might consider using a Centre Drill Bit (aka Slocombe Bit) which are designed to provide a starting hole for a larger-sized

drill bit.

¤ The Box Section

Paul mounted a rectangular block clenched between the side edges of his

o'Donnell jaws and turned the exposed end to a cylinder of sufficient length for

the outer box.

A Jacobs Chuck was fitted to the tailstock and Paul selected an appropriately

sized Forstner bit with a toothed rim. Originally, a Saw-tooth Bit was used for

drilling down end grain and a Forstner Bit for cross grain.

The lathe was set to a slow speed and a hole was drilled to about 30mm depth.

Top Tip

: When using a Jacobs Chuck, the

operation works well while under the positive pressure of winding the drill into

the piece but upon withdrawing, the bit can bind onto the inside of the cut hole

and get pulled out of the morse taper. Suddenly, a perfectly still drill chuck

with gear teeth has started revolving at the speed of the lathe. Anticipate this

by supporting the chuck to stay in the tailstock with your free hand gripping it

clear of the gear teeth.

Top Tip

: When using a Jacobs Chuck, the

operation works well while under the positive pressure of winding the drill into

the piece but upon withdrawing, the bit can bind onto the inside of the cut hole

and get pulled out of the morse taper. Suddenly, a perfectly still drill chuck

with gear teeth has started revolving at the speed of the lathe. Anticipate this

by supporting the chuck to stay in the tailstock with your free hand gripping it

clear of the gear teeth.

Having checked the depth of the hole, Paul marked

where he planned the base of the box to be with a narrow Parting Tool and shaped the outside to a thinner

body. He sanded through the grits on the outside and also, more importantly, the

inside using abrasives wrapped around a pencil.

To add interest, Paul used his Decorating Elf, brushing off resulting fluff

with a stiff bristle brush, used a Point Tool to define outlines and then a Taut

Wire to burn mark them taking care to keep the burn colour similar.

He parted off (still using double width cuts to avoid

jaming up his Parting

Tool) and then converted what was left in the jaws into a Jam Chuck to fit in

the drilled hole for reverse turning in order to finish the base.

He removed any centre pimple with a sharp Spindle Gouge or a shallow pointed

Skew, which cuts end grain very cleanly.

Paul applied decoration to match the sides although the circular burn marks had

to be done with a formica edge.

Finally, a touch up all round with abrasives, gently done to avoid any shrinkage

through sanding heat.

¤ The Lipstick

For a contrasting colour and lighter weight, Paul mounted a Sycamore blank as

previous.

Paul quickly turned it to a cylinder larger than the drilled hole of the box so

he could then carefully turn away the end with a Parting Tool, little by little,

regularly checking against the hole until the end could slide in & out without

any slackness.

He extended that diameter down the piece until further than the depth of the

box.

He used a Skew to turn the end to a point and at a slope that would leave the

cone shaped top reach full width below the lip of the box.

Paul sanded and decorated to match before parting off at a length that would leave the point just proud of the box,

Paul used the o'Donnell jaws to reverse mount the Lipstick and finish the

bottom.

The entire Lipstick was finally highly polished and placed in its box.

And the solution to the puzzle - blow it!

Providing there is a step down inside the lip of the box, a sharp puff will be

funnelled down the side of the lipstick and pneumatically raise it up and out.

(click for close up view)

The Sticky Ramrod

The punter is told of the importance of packing wadding tightly in a cannon and

that in Nelson's time, there was a device fitted to ensure the cannon would fire

its shot properly every time without misfiring. It used a rubber rope fitted

inside the barrel which the ramrod could hook up to and tamp the charge more

efficiently. Here is a scale model and this is how it works. The problem

was that only a skilled seamen could twist the ramrod the right way to make it

work. Let's see if you have what it takes to be a Master Gunner.

¤ The Cannon

Paul mounted a 5" x 1" block of Beech as above but supported with the tail stock

while turned to a cylinder.

With the tail stock withdrawn, the end was squared off with a shallow pointed

Skew.

The Jacobs Chuck was re-fitted and as the end cross-section was quite small, Paul elected to

start with a Centre Drill Bit before using an 8mm twist drill to bore a hole

almost to the end.

Paul turned the

outside to the shape of a ship's cannon.

A tiny hole was drilled on each side opposite each other just short of where the

internal bore ended so that a string of rubber could be threaded through and

glued at the holes.

The cannon was sanded, decorated and the back end (the Cascable) was

turned before it was parted

off.

¤ The Ramrod

A dense piece of Yew was mounted between his o'Donell Chuck and the tail centre to

make a stick in the shape of a ramrod.

Using a Roughing Gouge to start and a Parting Tool with an Outside Spring

Caliper for turning the diameter away with precision, Paul turned the blank to a

cylinder with 3 sections (evenly spaced out) having been carefully turned down

to just under 8mm but keeping a cylinder of wood at each end.

The Roughing Gouge was then used to turn away the wood between the 3 sections.

As the piece was getting quite thin, Paul rested one hand on top of the piece

immediately above where the gouge was cutting. This allowed him to lightly

press against the upward force of the gouge tip cutting the wood.

Each ramrod end was shaped as shown in the photo below before being well sanded and

parted off.

The distance between the cannon lip and the rubber was measured and a notch was

made on the ramrod at a position where it would engage with the rubber string

before the rod was fully in the barrel. Finally it was touched up all round as

necessary and highly polished.

(click for close up view)

And the solution to

the puzzle - it's like squeezing a slippery lemon pip.

The rubber string is a red herring - after the glue had hardened, a drill bit

was shoved up the bore and broke it so there is nothing for the notch to catch.

When the Puzzle Maker demonstrates his 'skill', he pulls the ramrod out as if it

had resistance and by subtly squeezing forefinger against thumb, the ramrod will

fly out of his fingers and smack back into the bore; all due to the end shape of

the ramrod.

The September Competition was set for a

Puzzle or Trick incorporating elements of turned piece(s)

<Competition Results>

<to

index>

June 2022 -

DEMO 2

Bird

Box

with Paul Reeves

Bird

Box

with Paul Reeves

Thursday, 16th June 2022 at MWCC Club Night

You might have previously turned a Christmas Tree ornament in the shape of a

bird box, but to turn one of full size would waste a lot of wood, unless you

started with a log.

(click for close up view)

(click for close up view)

But before that, it is worth researching expert advice on sizes, designs and

finishes.

A good place to start is from the RSPB <here>

Leaving aside where and how to attach your bird box, some thought has to be

determined about external & internal sizes before mounting your chosen log.

Apparently, the rougher the finish, the better for the occupants.

Inside walls must be rough enough for chicks to grip when they try to go for

their first flight.

In times gone past, a perch was invariably incorporated but isn't any longer as

they tended to be perfect for predators to lay siege on the nesting tenants.

Paul had considered making a box out of staves and bound like a barrel but

decided upon a relatively straight log just over 6" in diameter. He had

started at home on a Graduate lathe because it was large enough to prepare the

body and roof with the log as a single piece.

Paul had considered making a box out of staves and bound like a barrel but

decided upon a relatively straight log just over 6" in diameter. He had

started at home on a Graduate lathe because it was large enough to prepare the

body and roof with the log as a single piece.

If you have a smaller lathe similar to the size of the Club's, then you will

need to saw the log into the two component parts and prepare them separately.

Whichever method you use,

■

Mount the piece(s) between centres;

■

Leave one half of the roof section untouched to ensure that the bottom of the

roof will be bigger than the diameter of the body - this will allow the roof to

sit below the top of the body and avoid rain getting inside;

■

Create a spigot on the bottom of the body section and another spigot on

the top of the roof section to fit any reasonably large

and deep jaws that you have for your chuck.

Paul's Leylandii log had been a victim of February's Dudley & Eunice storms. It was

tight for the RSPB suggested dimensions but their sizes were suited for a

rectangular box whereas Paul's was for a circular box, which after all is a more

natural shape for a nest.

Shaping the Body

The body section was then mounted using the freshly turned spigot in the selected

sturdy jaws and the outside was trimmed up with a Roughing Gouge.

(click above for close up view)

Next, the centre was bored out with a Woodcut Pro Master Deep

Hollowing Tool which could secure Twist Drills Bits and Sawtooth Bits with grub

screws. Paul did try using a Sawtooth Bit initially with a toolrest

helping to start the central bore-hole accurately, but he found that it soon got

clogged with soft wet fibres so changed to a twist drill bit. Once the

central hole had been started, the toolrest was moved out of the way because the

rotating mounted piece kept the tool handle steady while the twist drill

progressed precisely down the spin axis centre. The hole

would eventually go through the entire body and out the bottom to act as a

drain but because of the limited length of the drill, this had to happen in

stages as the inside was hollowed.

The body was now ready to hollow out to the determined diameter & depth.

From the photo above :-

the top 2 are 'pick' tools which are easier to control but work rather slowly

because they produce small shavings;

the middle is a 'tip' tool which handles similarly as the pick tools but

slightly quicker;

the 4th is a Woodcut Pro Forme with the brass cap acting as a bevel;

and the bottom is a Rolly Munro articulated hollower. The bottom 2 do a much

quicker job but need practice to work efficiently.

There is one other option not shown above but had to be employed before these

specialised tools came along - a hefty Spindle Gouge used very gingerly and

taking a long time to complete the job.

Paul selected the Rolly Munro and started hollowing from the

centre outwards.

Ordinarily, one would aim to avoid producing vibrations and keep the cutter

running evenly to maintain a smooth finished surface, but the inside surface

needed to be a little rough, so hollowing out was progressed at pace.

Paul's technique was to have the tool handle pinned between his body and under

his arm while using his body weight rather than arm muscles to keep the tool

level with a consistent cut.

As the depth progressed, the ideal ratio of 5:1 either side of the toolrest

wasn't possible so his left hand needed a strong grip to hold the tool down onto

the rest.

Also, it was important not to lose the central hole. Because Paul hadn't

managed to breach the bottom of the piece earlier, he returned to his Twist

Drill Bit once he had hollowed out enough to allow the Woodcut Tool Handle to go inside the

body without touching the sides. Eventually, he managed to extend the central

bore right through the spigot to form the drain hole.

Knots can block the tool head with poorly cut shavings and need to be cleared

immediately as they prevent the cutting edge from working. He continued to

his planned depth and rounded off the inside floor like a natural nest. Having

checked for even thickness of the walls, he used a Spindle

Gouge on the outside and turn a curved bottom to match the inside shaping.

Having determined the size

and position of the hole as guided by the RSPB advice sheet, now would be a good

time to drill the entrance, although Paul had done this before the

demonstration.

(click above for close up view)

Shaping the Roof

This project is a great exercise for just getting on with the shape

as there is no worry about the resulting smoothness or finish.

The roof section was mounted using the prepared spigot and Paul levelled off the

base.

He had decided to create a dome in the centre and incorporate a recess to fit

the current chuck in expansion.

Having marked the required chuck diameter with callipers, he used a Spindle Gouge

starting from inside and carefully cut out to the mark. He finished off with an

angled scraper to match the dovetail of the jaws.

Then he used the callipers

again but this time set to the external diameter of the completed body and marked another circle in the roof's base and cut as above so that the

Bird Box body

could be inset into the roof.

He used a Parting Tool to enlarge and square off the inset

rebate to a close

fit.

These shavings were dusty as he was now scraping end grain.

This now allowed an opportunity to reverse turn the Bird Box

body and finish shaping it's rounded bottom.

With the roof still mounted and the body pressed into it's rebate by the tailstock

pressing against the newly drilled drain hole, you could turn away most of the the spigot and

shape the bottom of the body, before removing from the chuck and chiselling off the remnant

hollowed stub.

The roof was turned around and mounted into the newly cut expansion recess.

Top Tip : After cutting a

recess for an expansion dovetail, nearly tighten the jaws and hand turn the

piece - this will help clear out the bottom of the groove and allow the piece to

be held perfectly square.

The roof not only keeps the nest area dry;

it can also be designed to deter predators e.g. a spiked minaret!

Finishing the Outside

As recommended by the RSPB, apply any finish to the outside only.

Paul wanted to leave the roof as turned but disguise the body by 'scorching'

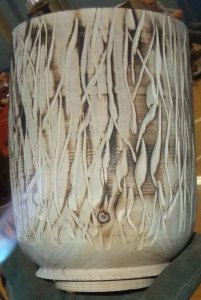

then using a Proxxon Long Neck Angle Grinder with a Carving Disc.

He used a blow torch to lightly blacken the body

(executed outside the Fire Exit in order to avoid setting off the Hall's

alarm!).

As the piece had to be removed from the lathe, a sensible precaution was to wear

an appropriate glove on his hand in front of the flame.

The Proxxon carving tool looks intimidating but isn't when handled with respect

and a bit of practice.

With the piece secured in the chuck, one hand held the

body of the grinder while the other hand remained on Paul's side of the

cutters, either switching the motor on/off or supporting the other hand or

rotating the chuck.

When switched on, the rotation of the cutters will be trying to move the grinder

away from your body.

Paul's technique was to just gently stroke the wood while pulling the grinder

towards himself using just the corners of the teeth to cut.

If this is your first attempt with a carving cutter, it is probably best to

practice on scrap wood before attempting on your hard worked piece. You might

find it helpful to control the motion of one hand by supporting it

with your other - rather than have both hands gripping the tool.

The first cuts Paul made were horizontal just below the entrance hole to give

something for birds to grip upon landing. He specifically made the horizontal

cuts angled downwards so any water would drop away rather than collect in the

groove.

The rest of the cuts were vertical.

(click for close up view)

The July Competition was set for a Bird Box turned piece(s).

<Competition Results>

<to

index>

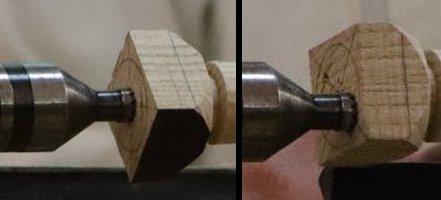

April 2022 -

DEMO 1

Unnatural Natural Edge

with Paul Reeves

Thursday, 21st April 2022 at MWCC Club Night

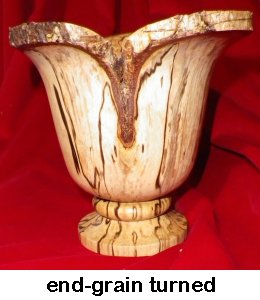

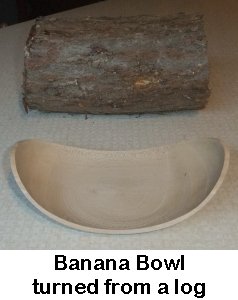

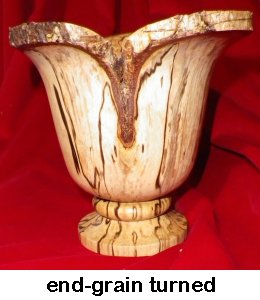

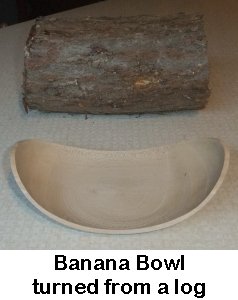

Natural Edge pieces rely upon the outside parts of the tree to improve

the final look of the turned piece, whether it is by retaining the bark or

stripping the outside edge to the Cambium Layer as seen in the Banana Bowl

below. The latter's often unexpected shape is produced by turning a log

'end over end' as if you were making a two-bladed propeller.

An

Unnatural Natural Edge is when

the edge has been 'embellished' prior to turning the intended piece.

(click for close up view)

(click for close up view)

These shapes can be achieved by first turning

between End-Grain centres (like a spindle) to create an outside shape, a tiny

part of which will become the edges of the piece when subsequently turned 'end

over end'.

Individual Method.

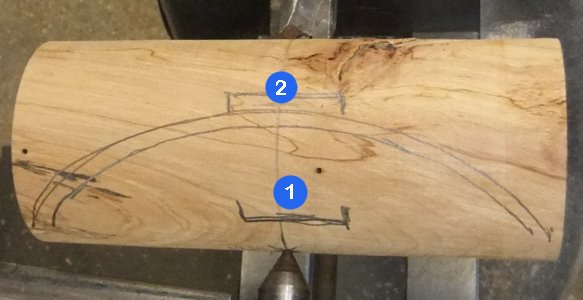

A log was turned into a cylinder and the

ends were squared off.

A pencil line was drawn down the length of the cylinder and its midpoint

circumference marked.

Top Tip : Now is an opportunity to draw

the pencil line so that any flaw on one side of the cylinder will be part of the

wood turned away from the finished piece.

Then the point 180° opposite was found using either the index of the

lathe/chuck; alternatively if your lathe hasn't any indexing, then by carefully

extending the pencil line through the end-grain centres and down the opposite

side so that the opposite centre will be found where this new line intersects

the previously drawn midpoint circumference.

With the cylinder still being

in/returned to its end-grain centres, a profile was turned into the sides.

Ideally, the shape should be a mirror image either side of the midpoint

circumference and avoid any sharp outward points as these are vulnerable to

breaking when turning end to end.

The shape was sanded through the grits as it will be the finished edge of the

final piece.

The piece was now mounted

between the end over end centres previously marked.

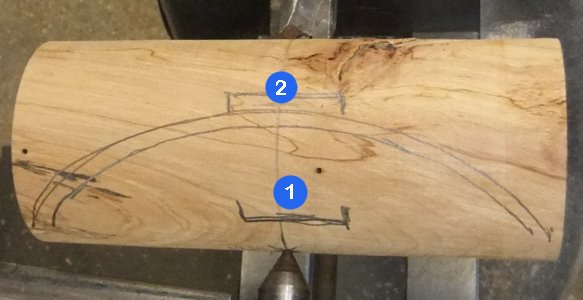

The photo below shows the planned outline for two spigots to be turned

The inside spigot (labelled ❶

in photo) is the first to be formed while between centres.

Then with that first spigot being mounted in a chuck (and if you feel necessary,

the opposite side being supported by the tailstock), turn away the outside to your desired shape while

creating the second spigot ❷

to where the base of the piece will be.

Top Tip : With the shape formed, sand

through the grits with a flat block held vertically so that it only touches the

wood perpendicular to its surface; this will ensure all leading edges will

remain crisp.

The piece was then reversed so that the base

spigot (labelled ❷

in photo) was now mounted in the chuck.

The piece was hollowed out to match the finished outside shape by carefully

maintaining an even thickness down the length of the profiled edge. Get

the thickness of the edges furthest from the centre accurate before progressing

inwards in order to maintain strength & integrity while working on the outer

wings.

Eventually, the inside spigot will be either turned away or shaped to

accommodate an embellishment (eg a candle holder; a box).

The inside surface should be HAND SANDED carefully to keep all edges crisp.

Reverse chuck to remove the remaining base spigot and to create a base/foot.

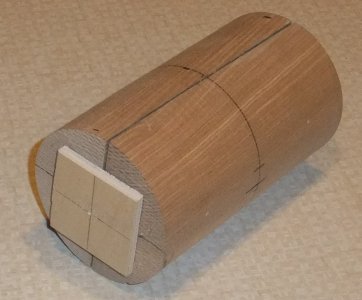

Pair Method.

Sometimes you will want to create a matching pair of intricate edged pieces.

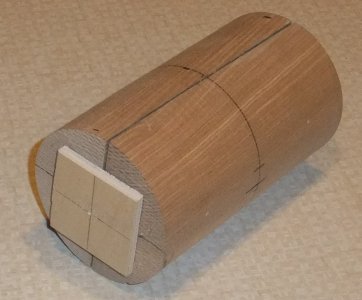

This is easily accomplished with two identically sized rectangular blocks.

Paul's happened to have two 6" x 3" x 1½" Ash blocks, which he hot glued

together to result with a single square ended block of 6" x 3" x 3".

He then hot glued plywood squares marked so that they could be mounted exactly

on the centre line of the combined block before turning between centres to a

cylinder.

Then as above, a midpoint circumference was drawn followed by two opposite

points for the end over end centres, but this time, of course, both had to be

90° from the glued joint.

(click for close up view)

(click for close up view)

Again as above, your chosen profile

should be turned into the cylinder; avoid leaving sharp points (unless very

dense timber is used).

Sand to a finish before taking apart the ends and glue joint, and divide the

cylinder into an identical pair of rectangular blocks.

Once the centres of the

resulting flat rectangular surfaces were marked, repeat the end over end turning

guidance described above <click here to find>

Factors

to Consider

►Lathe speed

is important - the faster the better in order to decrease the time

the tool is turning 'air gaps' (although speed is limited by any imbalance of

the piece);

►Move the

tool in a controlled smooth curve and allow the rotation to do the cutting;

►Don't

press the bevel onto the wood - else you will end up pushing the

tool into the 'air gaps' and the leading edges will become damaged.

The May Competition was set for an Unnatural Natural Edge turned piece or

matching pieces.

<Competition Results>

<to

index>

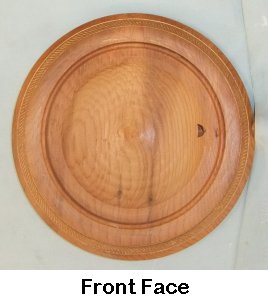

MAY 2022

Revision of

Bowl Turning Techniques

with Paul Reeves

Thursday, 19th

May 22 at MWCC Club Night

Thursday, 19th

May 22 at MWCC Club Night

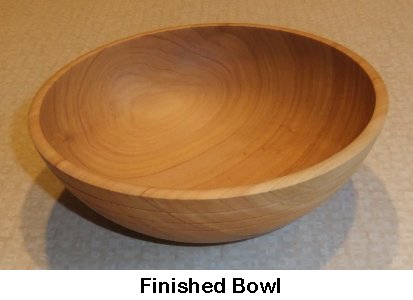

It seems that the general public believe all woodturners are able to turn

bowls so the expectations upon us are great. However, there is a lot to

take into account before you even pick up a bowl blank.

POINTS TO CONSIDER :

■ Use of Bowl - Decoration normally

gives added value but best avoided if

to be used

with liquid / food as it will be difficult to keep any grooves clear and clean.

■ Material Choice - a Fruit Bowl can be made of almost anything because it's

not necessary to be food safe whereas a Salad Bowl is restricted to non-porous,

non-tainting & non-toxic woods. So avoid Ash /Laburnum / Padauk / Purpleheart

/ Yew

etc and

stick to woods like Maple / Beech / Sycamore / Tulip Wood / American Plane etc

that are considered to be food-safe.

■ Size & Shape - Deep will hold a lot but not ideal for holding delicate

objects heaped up on one another. Open like a platter is good for showing off

what is there but a high-sided or undercut bowl edge is better for tossing

salads.

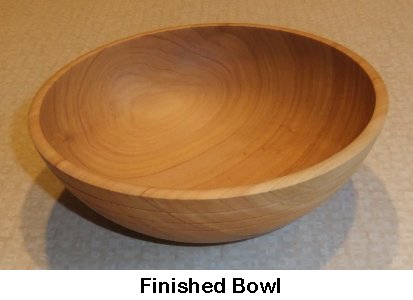

Paul had selected a 7" by 3" Macrocarpa bowl

blank to highlight that although it can tear a lot when turned, with sharp

tools, a clean thin walled example can produce a sturdy bowl like the one he has used for years to keep

the

family's keys tidy.

Macrocarpa is a coniferous tree endemic to California

where it is known as Monterey Cypress and also prolific in New Zealand after

introduction in the mid 19th century. It is denser than most

pines and more resinous which gives off a smell for a long time before it dries

out. But once dried, it is very durable and holds shape well even when turned to

a thin walled vessel.

■ Mounting on Lathe -

Having decide which end would be the base after a look for figure / faults, he

mounted the piece on the lathe using a screw chuck. (An alternative could have

been between centres)

Because he was using a flat plate screw chuck held within jaws, he bevelled the

pre-drilled hole in the top surface to prevent any scurf created as the Screw

Chuck bit a thread into the blank, which could have prevented the piece from

being held flat against the chuck's plate.

■ Tail Stock - Whether to use a tail stock to help support the piece would depend upon how

big the blank was and whether you were going to take deep cuts like a 'Show

Pro'! This was a small blank and there was sufficient time to take

measured cuts so leaving the tail stock off allowed Paul better access to the

piece.

■ Choice of Gouge - A Bowl Gouge is the

obvious answer but how long should the handle be? If your drive head is

fixed and you are not using a Tail Stock, then a short handle is better in order

to avoid being hampered by the rails. However, some lathes have drive heads that

can be slid towards the end of the rails to emulate a short bed option, which

can accommodate long handles.

■ Choice of Cuts - The gouge can be used as

a 'Push Cut' (produces a clean bevel finish) or a 'Pull Cut' (results in

deeper/quicker removal and gets closer to the intended foot but gives a rougher finish).

A Pull Cut needs careful technique as only the radius of the curve and a little

of the wing should be in contact to generate a controllable cut. This is

achieved by presenting the bevel parallel to the wood surface with the flute

facing towards your left shoulder to ensure the wing is supported.

Providing your tool rest is close enough to the curved surface, you should be

able to start with a Pull Cut and by rolling the front radius of the gouge, you

can turn into a Push Cut within one smooth pass.

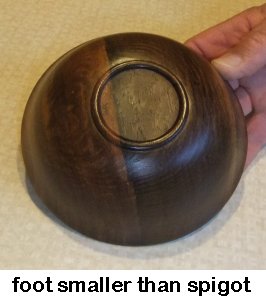

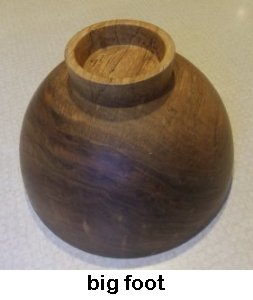

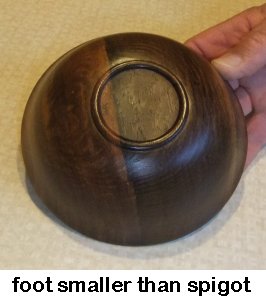

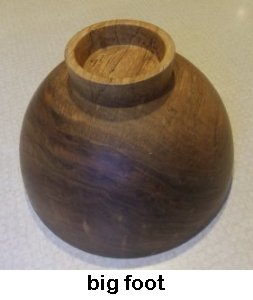

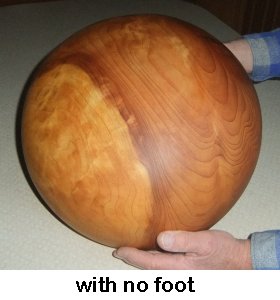

■ Plan the Foot - Don't let the chuck decide

the size of the foot. Big bowls need a foot outside a spigot for standard jaws.

The foot position will influence the chuck jaw mounting for hollowing with

regard to whether a 'compression' spigot (needs depth for a good grip) should be

created or an 'expansion' dovetail (reduced depth required but must have enough

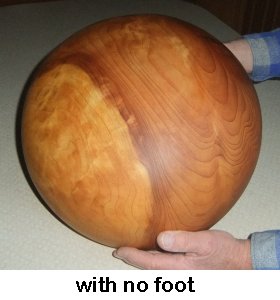

wood strength outside the dovetail). You could decide upon no foot, but is

prone to rock. Once decided which jaws to use, set

your dividers to the appropriate size and remember when scoring the base, only

the LHS point touches the work - the RHS point must only touch air.

■ Squaring off Spigot/Dovetail - When

turning a bowl (except with an end grain bowl blank) there is often a problem

cutting across the end grains and ending up with fluffy strands which can hinder

the jaws from holding the piece centrally. Parting Tools and Skew Chisels

don't work as well as a small Spindle Gouge which will 'cut' the end grain

rather than scrape across them. A sharp gouge and moving the tip

slowly across the surface will also help.

■ Tools to Help Shaping - Shear Scraper

using a straight cutter for external and curved cutter for inside shaping. Lead

with the handle and angle the cutter against the wood surface away from being

horizontal.

■ Finishing - Mark the spigot's centre

point before detaching from the drive head to aid eventual reverse chucking removal. Sander Seal all

end grains and any tear-outs near faults before making your final pass with the

gouge. Try to move from start to end without stopping.

■ Decorations - Lines and marks can be made

with any SHARP pointy tool but avoid going too shallow as they might disappear

after sanding. Burnishing marks with wire tend to vary intensity when passed

over cross grain then end grain but Formica Burnishing is much better.

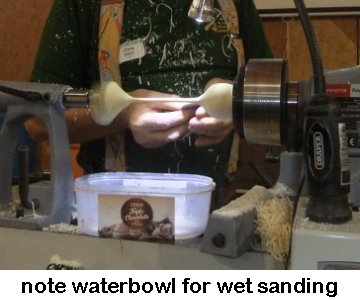

■ Abrasives - Beware getting your work

too hot while sanding with the piece turning. Some woods (eg Yew, Macrocarpa)

get hot from friction very quickly and can end up cracked. This danger is

reduced by slowing the lathe speed and by regularly keeping the abrasive clear

of dust build up with a wipe across a piece of carpet.

With the outside surface finished and sanded, Paul took the piece off the

screw chuck and set up the chosen chuck jaws to grip the prepared spigot.

He then squared off the face with a combination of pull & push cuts with the

Bowl Gouge.

■ Shape of Inside - Lots of options

:- a small hollow in the centre; match the curve of the outside; curve the rim;

undercut the rim.

■ Direction of Cuts - For an Outside

Curve, cut from the axis of spin towards the outside. (NB: you often have to cut

a small area the other way in order to get a clean corner up to a spigot /

foot).

For an Inside Curve, cut inwards from the rim towards the axis of spin.

With a gouge with a swept-back grind, you have to steer the gouge tip above the

horizontal in order to avoid the metal bar of the gouge crashing into the rim but must steer back to end the cut at the spin axis. If

the bowl is particularly deep or has an inside curve with a sharp change of

direction, use a Bowl Gouge with a large bevelled angle (eg 70°) to help get a continuous

cut from rim to centre.

■ Tip Control - Be aware that until

the bevel can give support, the gouge tip has a tendency to slip outwards when

starting the cut. This is alleviated with a positive control of the gouge bar

where it lays on the tool rest and of the handle in your other hand.

As your cut moves towards the centre, the rate of the turning wood passing the

tool tip reduces so you should slow your movement as the tip gets closer to the

spin axis.

Try not to interrupt your cuts as it will spoil your 'muscle memory' for the

final cut. Make sure you have a sharp gouge before you start and get the

thickness of the bowl's wall uniform and accurate well before the last cuts.

There is an argument for making that last cut large rather than trying to skim

in one movement. This will lead to a cleaner cut and less angles to try to sand

out.

Angle the tool rest into the hollow to reduce the amount of gouge over-hanging

as it sweeps around the inside curve.

If the bowl is to be thin walled, work on getting the inner surface near the rim

close to the desired thickness before working further down the bowl. The extra

thickness in the bottom will discourage the thin walls from flexing during your

cuts.

With the inside sanded, it was time to reverse the piece in order to remove

the spigot and finish the foot. The first thing Paul measured was the thickness

at the bottom of the bowl. This confirmed how much of the spigot could be

removed.

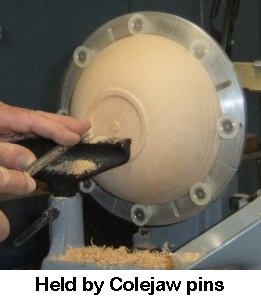

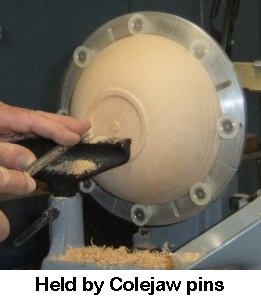

■ Reverse Chucks - There are

several ways to hold the piece for the next job.

Use an MDF faceplate with a groove cut into it to exactly fit the diameter of

the rim OR Press the piece against a flat faceplate while holding it

in place with the tail stock in the pockmark previously made when forming the

spigot OR Colejaws;

Whichever method is used, nibble the spigot away with a Spindle Gouge cutting

inwards towards the head stock - if you try cutting across, the same problem

with fluffy end grain will arise.

Paul had chosen to use Colejaws, so he protected the surface of

the rim with some masking tape before putting the piece in and tightening the

jaws.

Now that he knew how much he needed to remove from the base, he deliberately

left a pimple at the centre to give an accurate gauge of the depth removed and

then cut it away with the last cut.

<to

index>

FEBRUARY 2022

Demonstration of

Sphere Turning Plus

with Paul Reeves

Thursday, 17th February 22 at MWCC Club Night

Spherical shapes are predominantly used in games and for decorations.

If a large number of same-sized wooden balls are required (for

example a solitaire

set) then purchase from an eBay supplier might be the quickest, most economical

and accurate method rather than making them yourself. (Feb

2022 price for 50 of 20mm diameter beech wooden balls = £10).

But a perfect sphere is not always necessary. For example, a ball used in a

coconut shy needs to be more robust, dry and stress-free than be perfectly

round.

For a decorative ball in natural finish then a perfect sphere would be

preferable and the choice of wood should be something interesting; for example

burr or figured or chatoyant.

The 'Plus' element is referring to starting with a ball and then enhancing by

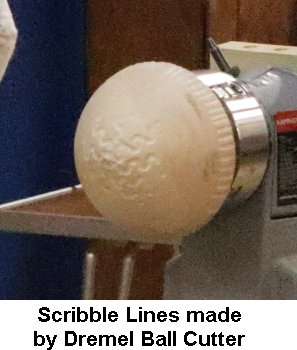

carving, hollowing out or colouring.

In fact, you don't even have to start with a ball.

There are several options to turn your own sphere :-

Buying a Ball-Turning Jig - expensive

Roughly turning with a round cutter -

difficult to control

Rubber ring chuck with a rubber ring tail stock -

inaccurate if rubber flexes

Wooden Cup Chuck method

Paul demonstrated using the Wooden Cup Chuck method.

A rectangular block of Yew had been prepared with it held between centres and

turned to an even cylinder.

He set an External Caliper to the diameter of the cylinder (which would become

the diameter of the sphere). With this set Caliper resting approximately

centrally on top of the cylinder, he marked the two ends of the Caliper with a

pencil and then with the aid of the tool rest, drew two pencil lines around the

cylinder to mark the extent of where the edges of the sphere would be.

He set an External Caliper to the diameter of the cylinder (which would become

the diameter of the sphere). With this set Caliper resting approximately

centrally on top of the cylinder, he marked the two ends of the Caliper with a

pencil and then with the aid of the tool rest, drew two pencil lines around the

cylinder to mark the extent of where the edges of the sphere would be.

Using a ruler, he calculated and marked another circle around the cylinder half

way between the previous two lines. This circle became his starting 'meridian',

which from now on, SHOULD NOT be cut any smaller (although

might end up being so later to correct errors!).

The two sphere edges had to be kept clearly defined with a Parting Tool so that

the outer edges of the sphere wouldn't get lost.

A spindle gouge was used to turn a curve like a giant bead which started at the

untouched centre meridian and would have eventually ended vertically at the

centre of the wood but for Paul refraining from completely parting through.

As the curves progressed, Paul had to return to using the Parting Tool in order

to prevent losing precisely where the ends were going to be.

Once he had reduced the attached ends to about 5mm (and

the curves not quite yet vertical), Paul stopped the

lathe and after taking the pressure off the tail stock, used a saw to detached

the approximately shaped sphere with 2 small stubs at opposite ends.

Making a Cup Chuck

End Grain is preferable as it is less likely to distort into an oval shape as

the wood moves with age/humidity. A softer wood than the object wood is also

helpful.

End Grain is preferable as it is less likely to distort into an oval shape as

the wood moves with age/humidity. A softer wood than the object wood is also

helpful.

With a suitable blank mounted between centres, turn a spigot at one end to fit

your lathe chuck.

Then with that lathe chuck fitted and holding the spigot of the Cup Chuck,

square off the face and drill/gouge a hole down the centre in order to help

hollowing out.

The hollow across the face should be fractionally less than the diameter of the

sphere but definitely deeper than its radius to avoid the sphere from 'bottoming

out' when fitted into the cup.

Should you inadvertently hollow out the width too much, then further squaring

off will reduce the diameter because of the bowl shape of the hollow - but

remember you might need to deepen it further to avoid bottoming out.

Working with the Cup Chuck

Fit the sphere into the cup with the starting 'meridian' at right angles to the

face of the chuck. A slap with the palm of your hand should result in a good

grip provided the two small stubs from the previous turning do not protrude too

much.

The aim now is to use a narrow Parting Tool to create another meridian just deep

enough to match the depth of the starting meridian at the 2 points where they

intersect.

To achieve this, increase the lathe speed, then very VERY gingerly move the

narrow Parting Tool inwards so that it gently nicks the stubs. Stopping to draw

a pencil line along this new meridian will help to judge when your depth is

enough. Continue to gently part away until the pencil line almost disappears

before stopping and checking the depths where the meridians intersect. Repeat

until the intersections are of matching depths.

A Spindle Gouge can then be used to turn away any excess above the two

meridians. Move the tool rest so that the gouge bevel can touch the rotational

axis point or 'pole' where the surface will be perfectly level and therefore no

buffeting vibration will be sensed through the gouge when the lathe is turning.

However, once you move away and come across something higher than the meridians,

you will feel, hear (and possibly see) the tool buffet.

The next steps require precise and delicate control of the gouge tip.

Slide the bevel back sufficiently for the gouge tip to reach where the buffeting

started and allow the tip to just cut some dust; then carefully and steadily

move the tool forward to cut away a very thin layer; stopping if the tool starts

to run smoothly. Backtrack using the bevel and test for buffeting. Repeat the

delicate cutting until the buffeting dissipates. Smoothness can be assessed

with a light touch of the surface at the top of the piece with your thumb

pointing towards the direction of rotation.

Once this hemisphere is nearly even, a straight edged skew can be used to gently

smooth out any bumps sensed by your thumb, but keep the tool's contact moving at

all times.

When satisfied, slow the lathe speed down and briefly sand with abrasives. If

abrasives are used too much, there is a likelihood that more surface will be

removed on the side-grain than the cross-grain sides resulting in the sphere

appearing pointed.

The abrasive can be hand held or used with a flat block, but in both cases keep

the abrasive moving and parallel to the point of contact.

Next, the sphere was removed. It might require a mallet to tap the Cup Chuck in

the direction towards the head stock, but be ready to catch it when it pops out

with the first tap. (Do try to avoid hitting the sphere of course!)

The sphere is reversed to tackle the remaining hemisphere.

However, the Cup may be too large for the previously trimmed hemisphere so a

quick squaring off the face of the Cup Chuck as described above will narrow the

opening. Remember to check if the bottom of the hollow needs deepening.

Repeat as above to remove all the surface that is standing proud of the

meridians.

Short use of abrasive and your sphere will be complete.

<to

index>

January 2022 -

DEMO 5

Added Value

to a

Two-Part Candlestick/Lamp

with Paul Reeves

Thursday, 20th January 2022 at MWCC Club Night

The basics of two part turning was covered in

Spindle & Face Plate Turned in January 2020

with a three-legged stool. <available HERE>

This time we are turning a candlestick/table lamp with "added value".

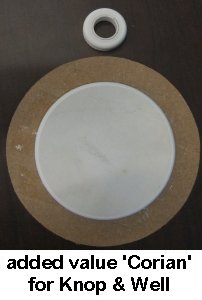

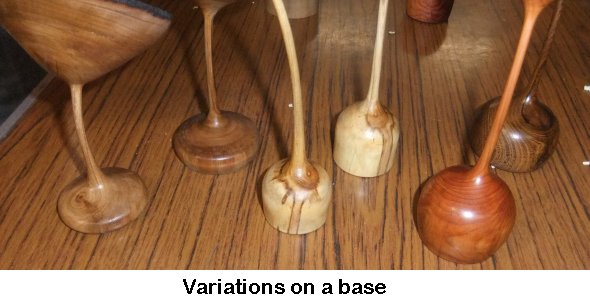

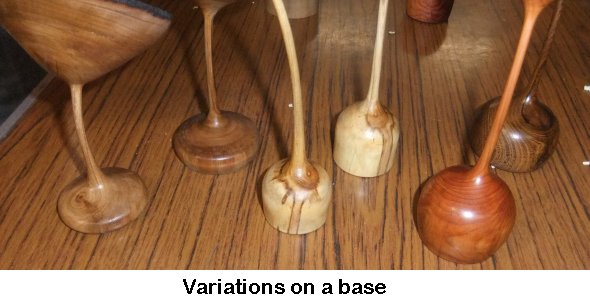

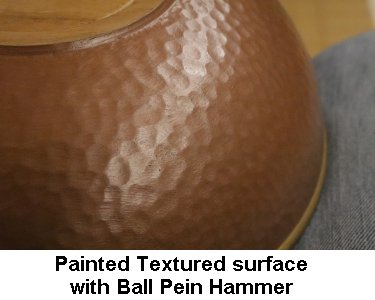

Some examples are shown in the adjacent photos :

●

A Victorian Table Lamp with a shoulder at the top, elegantly turned and enhanced

with gold colour highlights.

●

A plain wood decorated with a base coat beneath a top contrasting coat, which

was wiped before drying to expose the base colour in places.

●

A slender column enhanced with a knop (ornamental rounded protuberance) painted

or conjoined with a different colour or wood type.

●

Paul's oversized candlestick with its added value of a large piece of copper

plate, which doubled as a fire precaution as well as the spiked seat for the

large candle above.

This demonstration is a Table Lamp with the added value of alternative

embellishments, e.g. Corian.

(Corian is a man-made mix of minerals and acrylic typically used in worktops and

can be turned on the lathe with a scraper.)

Top Tip : As synthetic materials tend not to move with

humidity, best to select dry wood for the wooden parts of the piece to avoid

loose joints when it inevitably shrinks inside a home.

Paul is using some surplus Corian-like material that had been

developed for aircraft interiors; however it can be worked the same as Corian.

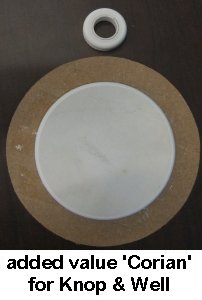

The Knops.

There were to be decorative rings at the bottom & the top of the stem.

To save time, Paul had initially used his bandsaw to cut out a circular piece of

his material at home (surprisingly, the bandsaw had no problem cutting an accurate

circle on these types of synthetic material). He had then mounted the resulting

disc within his chuck jaws and drilled a central hole of a size suitable for a spigot (soon to

be turned on the stem so it would fit securely into the base).

Next he created a Jam Chuck from a cylindrical piece of gash wood such that one

end could be secured in his chuck and the other end reduced using a

Parting Tool so that it just fitted into the hole of the Corian and had a clean

cut shoulder to hold the Corian perfectly square. He carefully made an accurate

saw cut through the centre mark of the working end (down to well below the shoulder line)

using a band saw or a tenon saw. With the the Jam Chuck attached to the head

stock and the Corian ring set against the shoulder, the tail stock was tightened

with its tapered point gradually parting either side of the saw cut until it

jammed the Corian fixed onto his chuck.

Corian doesn't have any grain so it has no problem being scraped into a bead

with virtually any piece of well honed metal. The scraper works best with a

negative rake and by keeping it moving while at a slower lathe speed than when

turning wood.

Paul scraped one half of a bead and squared off down to the Jam Chuck on the

tail stock side of the piece before sanding. Corian sands well but does need the

lathe slowed even further while keeping the abrasive clear and cool by brushing

a carpet against the grit. He polished the surface to a shiny finish with some

0000 wire wool before reversing the Corian on the Jam Chuck and repeating for

the other half of the bead to match the first half so that both sides were flat

and parallel to each other.

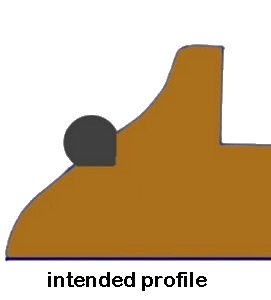

The Well.

This was to be a larger decorative ring resting in the upper surface of the

base.

Again, Paul had prepared a circular piece of his material attached centrally to

a MDF faceplate with double sided sticky tape.

The outer edge was fashioned with an undercut

using a scraper as before.

The scraper was then worked from the highest point towards the centre following

the curve already made.

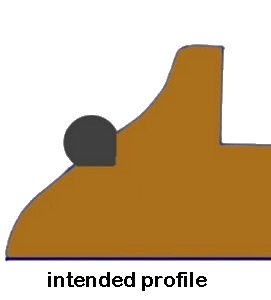

As seen in the intended profile above, the outer curved edge finishes at the

bottom of the material while the inner curved edge finishes higher up.

The desired shaped ring was cut with a parting tool straight into face of the

circular prepared piece.

The Base

For the demonstration, Paul had prepared the base by mounting between centres;

turned a cylinder of appropriate diameter; shaped an upper surface.

A hole had been drilled in from the side to the centre running close to the

underside and another hole drilled down the centre to accommodate an electric

cable to enter the base at the side and bend upwards and eventually through the stem to a light

socket.

The top of the base was mounted in a Screw Chuck.

The outer edge of the underside was squared off and the centre slightly

hollowed. A ridge was turned within this hollow at an appropriate diameter for

Paul's jaws to grip the base in expansion for the next step.

Having turned the base around, the top of the base was pared off sufficiently to

allow the first turned Knop described above to sit in perfect proportion to its

diameter. Then the same drill used to cut the hole in the Corian Knops was

placed in a keyed chuck & arbor fitted to the tailstock and used to bore a hole

sufficient to receive the spigot soon to be turned on the stem.

Next, the internal diameter of the shaped Corian

ring (that was to form the Well) was measured and marked on the base.

A Parting Tool was used to carefully get the width exact for the ring to fit

snugly.

Once the ring's inner edge was right, the Parting Tool was used to deepen the

cut a little at a time until the ring's outer edge became flush with the base.

The Stem

Having turned the stem between centres to a cylinder of a size to allow for some

shaping by the finish, Paul changed the tail stock centre from a pointed tip to

a hollow ring type, which allows for a Shell Auger to be used through the tail

stock for boring a long hole up the centre for the electric cable.

With the stem re-mounted between these centres, Paul placed the point of the

Auger at about half way along the outside of the piece and marked the Auger with

a piece of sticky tape adjacent to the back end of the tail stock.

He started the lathe and fed the Auger through the back of the tail stock until

it eventually started to bore into the stem.

It now required a gentle steady feed with frequent withdrawals to clear the

waste sawdust in order to prevent the Auger going off centre. Once

deflected, you would never be able to correct it back on course.

Once the tape mark on the Auger reaches the back of the tail stock, Paul

stopped, changed the 4-prong drive centre for a Counterbore Drive, reversed and

remounted the piece for boring the rest with the Auger. Paul advised that

he could feel the Auger in his hand go soft just as it broke through the first

hole.

The hollow ring tail centre was replaced with the pointed tip centre and the

stem returned to between centres with the tail stock supporting the end destined

for the Lamp's base.

After setting his Spring Calipers to the size of the drilled hole in the base,

Paul used a Parting Tool to turn a spigot of appropriate length & diameter to

fit the base, remembering to account for the depth of the first Corian-like

embellishment he had turned.

He then continued to finish shaping the stem and added a shoulder plus another

Corian-like knop to go beneath the light bulb socket.

Paul had a brass insert that screwed

directly into the drilled hole of the stem. This insert couples the bulb socket

to the stem.

Top Tip

: If a

Lamp is going to be sold at some point there are some electrical goods

regulations that must be followed eg. cable clamp.

To avoid this problem, the simplest way is to sell it un-wired with the customer

arranging for a competent electrician to do so.

And finally, below all the parts individually

and assembled with a coat of oil applied.

(click for close up view)

The February Competition was set for a two-part Table Lamp or Candlestick (base

and stem)

with "added value" eg colour, texture, other materials etc.

<Competition Results>

<to

index>

December 2021 -

DEMO

4

Box of Contrasting Woods

with Paul Reeves

Thursday, 16th December 2021 at MWCC Club Night

The wood types best suited for box making have

moderately tight and even grain which won't present too many turning problems.

The tops & bottoms of boxes are better designed to be end grain; even so, softwood options will invariably tear out whereas

hard woods tend to cut cleanly.

Popular choices are from the Rosewood and Fruit wood families. Woods to avoid

have well spaced and well defined growth rings with fluffy open structured wood.

Likewise, some spalted woods should be avoided if the paler parts are

significantly softer than the rest.

Paul chose to turn a small box made from Box Wood adorned with the contrasting colour

of Pink Ivory to give a seasonal effect.

Box is an ideal wood for very thin walls and finishes beautifully with Carnauba

Wax applied.

Pink Ivory can provide a natural shine even from a tool finish.

For the sake of saving time during the

demonstration, Paul had prepared the Box blank between centres, turned the piece

into a cylinder of desired diameter with a spigot suitable for his chuck at

each end.

He had then parted the lid from the base at approximately

⅓ : ⅔ ratio.

[ Top Tip

: Before dividing your original piece into box

lid & box base, draw a pencil line along the cylindrical side so that once

separated, any blemishes in the wood can be quickly lined up].

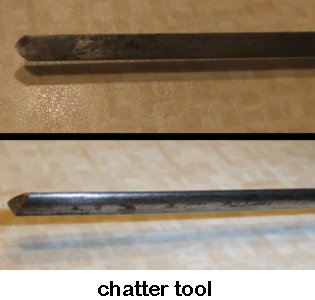

Cabochon

(a smooth domed ornament; polished but unfaceted)

With the Pink Ivory secured in the jaws of his chuck, Paul used a broad parting

tool to turn a cylinder to a suitable diameter and depth to fit within the top

of the prepared lid.

A dome was formed on the front with a small negative rake scraper. Ordinarily, if done carefully (ie

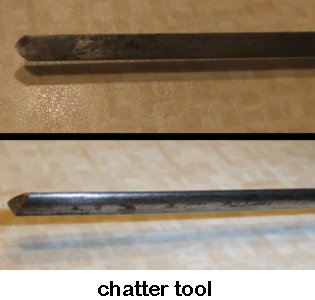

with no scratches) there would be no need to sand. However, as Paul was going to

decorate using a chatter tool, the piece needed to start from a very shiny

finish for it to show up later between the chatter marks. He achieved this with

400 grit.

A chatter tool should only be used on end grain because applying to side grain

would result in marks of differing depths as the piece turned between the two

contrasting densities of along & across grains.

The chatter tool works because its end is sharp and flexible. Its effectiveness

is improved by slowing the lathe speed down a bit and presenting the tool tip

pointed slightly down.

When satisfied with the resulting design, the disc was parted off to the desired

depth and any pimple removed.

[ Top Tip

: If the box base is going to be hollowed out

with a Forstner bit, the above process can be repeated and adapted to produce a

matching thin disc for the inside bottom of the box to hide the centre dimple made by the Forstner ].

Decorative ring to go around spigot of box base.

Using hardwoods makes it easy to get a precise fit.

With the Pink Ivory still in the chuck, Paul used his parting tool to turn a

cylinder slightly larger than the diameter of the box base - this will allow a

clean precise cut-to-size later in the process when the base and lid are taped

together.

Having calculated a suitable diameter for the spigot, he carefully transferred a mark to the front of the Ivory using dividers.

The centre recess was

removed to a few millimetres deeper than the planned depth of this decorative

ring.

This could be started with a gouge or a Forstner drill bit in a Jacob's chuck or

(as Paul chose) with an old drill bit in a handle held against the centre of the

front as the lathe was turning. Whichever way was selected, the final cut to

the inside edge was completed with a Box Cutter to the mark made by the dividers earlier.

Paul parted off the ring and cleaned up the surfaces (that would be glued to the

base) carefully with fine abrasives for a close fit.

Spigot on base

for decorative ring.

With the box base mounted using the prepared tenon, Paul squared off the front.

Having measured the inside of the decorative ring carefully with callipers, he marked

the same diameter on the front using dividers. The length of the required spigot

was calculated to incorporate the width of the ring and then sufficient to grip

the sides of the lid but avoiding making the lid's top too thin. Using his broad

parting tool again, he made a cut at the calculated length and formed a parallel

spigot to just short of the earlier dividers mark. The final fit was done

gradually with the negative rake scraper with regular cross checks against the

decorative ring. Paul finally glued the ring to the base using some superglue.

Inside of lid to fit spigot.

With the box lid now mounted on its

tenon, the spigot was measured with callipers and the underside of the lid

marked as described above.

To make this small recess, Paul initially used a spindle gouge from just inside

the dividers mark towards the centre and then from in to out towards the mark.

The box cutter was used for fine adjustments of both depth and inside diameter

with regular fitting cross checks with the spigot on the box base to avoid a

loose fit. [ Top Tip

: don't be tempted to use

abrasives at this stage because different densities around the piece will abrade

away differently and the recess would become oval. It would also be difficult to

maintain a square fit. A box cutter avoids both these problems ].

The correct fit was when there was a slight resistance to removing the lid.

Cabochon fitting.

Paul had removed the box lid from the

chuck, lined up the lid to the base using the pencil mark drawn down the side of

the cylinder at the start and closed the box. Some insulating tape (or similar)

was applied around and over the joint of the base & lid before mounting the base

spigot into the chuck. The lid's tenon was turned away and the process of making

a small recess for the cabochon was exactly as the previous paragraph - other

than the fit was finished by gluing the decoration into place.

Next, Paul used his spindle gouge to trim the insulating tape off, the

decorative ring back to the outside of the box and matched the lid to the base

to a smooth finished shape. Finally, Paul used a thin parting tool to mark

a groove where the bottom of the box would eventually be parted off. This

allowed him to calculate the maximum depth he could take from the inside of the

base.

Hollowing out base.

With the lid removed and the lathe started up, Paul used the tip of a skew to

mark the centre of the spigot. He now calculated how deep he wanted to go

inside the base measured from the top of the spigot and allowing for just how

thin he wanted the base of the box to be.

He took his old drill with its handle that he used above and marked this depth

with the aid of a piece of tape around the drill so that when its bottom edge

was flush with the top of the spigot, he would be at the correct depth.

With the lathe at a moderate speed, the tail stock well out of the way and his

old drill in his hands, Paul gently presented the drill tip to the centre mark

keeping it as level and square as he could tell before pushing the drill into

the wood. As it went deeper, the rotation naturally guided the drill to run

absolutely true. Paul only allowed the drill to go as deep as the leading edge

of the tape before withdrawing.

This hole made it easier for a gouge to remove the centre. Also, by keeping

close attention to the bottom of the box, he was able to see when he was nearing

the bottom of the drill hole and hence his selected depth.

The next decision was whether the shape of the base inside be curved (use a

round scraper) or square (use the box cutter). His audience opted for round.

Whichever is used, it is vital that the scraper/cutter must move horizontally in

and out.

Any slight deviation from level will result in the cutting edge digging deeper

into the wall of the piece as the tip travels further away from its pivot point

on the tool rest. The same problem arises if the tip moves away from being

parallel to the 'ways' (the rail-like metal bars that the tail stock slides on).

One aspect to remember when hollowing is that the walls will become heated by

the friction of the cutting tool. This results in driving moisture out of

the walls (the thinner the walls, the more the effect) and the diameter of the

box will shrink slightly. Suddenly your previously perfect fitting

lid has become very loose! Don't panic. Leave the piece alone

and after some 12-24 hours, the wood in the walls will have cooled, had time to

re-absorb the lost moisture from the natural humidity in the air and come back

to that perfect fit.

[ Top Tip

: don't try to turn

the inside of a lid to fit a spigot immediately after you have hollowed out the

base. You will probably end up with the lid welded tight onto the spigot ].

The tool finish on the Box Wood was good enough to proceed with parting off.

The thin parting tool was used in the earlier made groove and parted off the box

base from its tenon. If it had been necessary, the box bottom would have been

finished off by reverse chucking.

Paul changed his chuck for buffing mops, which he

used to smooth the surfaces with just the White Diamond compound. He feels that

the Tripoli compound with its red colour tends to darken the finish of the pale

Box Wood. Following a change of mops, he finished the buffing with Carnauba wax.

Don't put too much wax on the mop wheel as this can lead to a hard ring building

up, which will need wire wool to remove.

The technique for all the stages is a steady gently stroke of the piece

against the mop wheel and keep slowly turning it in your hands.

[ Top Tip

: spreading a folded towel or similar on the 'ways' underneath the mop wheel

helps to avoid dents if the spinning mop should rip the piece out of your hands ]

Pushing the piece hard onto or holding it still against the mop wheel will

result in a build up of heat which could distort the piece or burnish a flat

into the side.