I've finally finished this piece. It has being 'drying' on my bench for about 4 years!

Below are contributions from members during the Coronavirus Crisis for your

perusal and inspiration.

Perhaps you might be tempted to add something of your own, a comment or some

humour.

Contributions are in chronological order with the newest at the top.

(Spring 2020 - Aug 2021)

(Sun 1st

Aug) Paul Reeves writes :

I've finally finished this piece. It has being

'drying' on my bench for about 4 years!

Meanwhile, some miniature work - small threaded

boxes embellished using the 'Decorating Elf' & with tiny contents.

Boxwood spinning top in the first & a couple of 6mm high goblets with a bottle

of red wine in the other.

(Sun 1st

Aug)

David Hamilton has finished a piece from Paul's latest Monkey Puzzle log.

The inside is finished with Lemon Oil and the outside with a light wax polish.

(click for close up view)

(click for close up view)

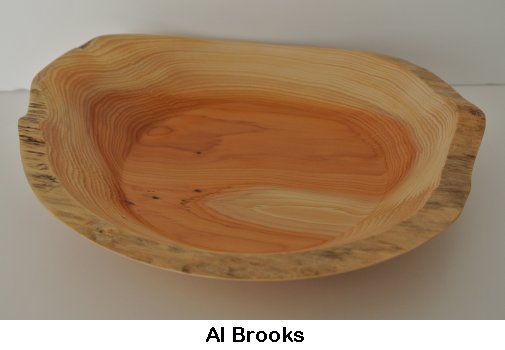

(Fri 16th Jul) Alan Brooks reports :

Below was

a well seasoned piece of Yew that had been in the workshop for a very long time

but I decided its time had come. The end result is 10” wide x 7” tall x .75”

thick. Finished with sanding sealer and Renaissance wax. Due to the imbalance

of the piece it rarely got to spin above 400rpm!

(click for close up views)

(click for close up views)

(Fri 18th Jun)

Vic Russell writes :

A couple

of recent turning projects,

A collet handle with cork grip ...

(click for close up view)

(click for close up view)

... & an Incense Burner woodturner.

(the incense cone sits in a brass cup and the smoke comes out of the mouth)

(Fri 11th Jun)

A few more contributions from the Patrick and Beddoe workshop :

All crush grinders made from Magnolia with the exception of

a Rook out of Laburnum and another out of a combination of Oak & Purple Heart.

(click for close up view)

(click for close up view)

The star turn biscuit barrel

shows Geoff having a bit of fun using up bits and pieces. The body is Apple,

top/bottom rings are Lacewood, lid is Oak, handle is Mahogany, lid knob purple

heart and handle pegs are Olive.

(click for close up view)

(click for close up view)

(Sun 25th Apr)

Top Tip

from Paul Reeves :

For the quickest way to peel a lump of wet

Monkey Puzzle :-

Mount the piece straight onto the lathe either between centres or on a

faceplate;

Turn away the hard bark and the softer next layer (the Cortex) which will come

off in long strips;

The next layer (the Phloem) is very fluffy and just clogs over the edge of the

tool, so stop the lathe;

Then with an old chisel, push it under the fluff from the end and prise it all

off.

The chisel slides very easily with a tap of a mallet along a slippery skin (the

Cambium Layer) just outside of the sapwood.

You should now have a lump with all of the knots sticking out .

Remember to turn it as a big spindle blank, cutting from large to

small diameter on the outside.

The picture shows the last bit about to come off a very wet log.

(Wed 21st

Apr)

It's that Alan Brooks again! :

Couldn’t

wait to play with some of the Monkey Puzzle that I picked up on Saturday from

Paul.

After spending some time stripping back the bark and sapwood have now got a 5 x

7” bowl (4mm thick) which hopefully will not split after being stored in

shavings for a while.

(click any for same larger view)

(click any for same larger view)

(Sat

17th Apr) Alan Brooks

reports on two of his recent pieces :

Having seen this idea on Pinterest, I had some old Ash with

its bark having a deep craggy effect. I needed to work out where the hole for my

tailstock would be (eventually to house a test tube) and then line up the screw

chuck to fit my head stock. On an earlier attempt, I had drilled the test tube

hole first and then supported the work with a revolving centre whilst on the one

pictured, I drilled the hole near completion so that I could shape the neck more

precisely while it was better supported. Due to the offset, I could only run at

about 300rpm using a large Roughing gouge to get it started but was able to

increase speed as it took better shape. I kept with the roughing gouge for much

of the side grain work and used a 3/8" bowl gouge to shape the top and small

spindle gouge to refine the neck of the test tube opening. I suspect because the

wood had dried out slowly and naturally, it remained stable and the bark has not

shown any sign of peeling away. The only thing that has been applied is sanding

sealer. Keeping the gouge sharp and doing the final sanding by hand seemed to

avoid tearing out the bark.

(click for close up view)

(click for close up view)

The Maple below had been cut down nearly 5 years ago.

This piece was at the very base of the tree which resulted in some of the

interesting markings. I used a large bowl gouge to remove the craggy bits to get

the initial shape and then mostly use a 3/8" bowl gouges with different grinds

to do the shaping. I don’t purposely pick a timber when it comes with

voids and holes but when they are there, it is quite exciting to see how far you

can push yourself without causing damage to the wood, oneself or one's tools.

(click for close up view)

(click for close up view)

(Wed 14th

Apr) Paul Reeves writes :

As I reported below (here),

I had obtained some Ginkgo Biloba (aka the Maidenhair

Tree) and I have now turned a 15" Serving Platter from a plank that had been

exposed to the elements for 18 months. Interestingly, there was very little

surface degrade or checking other than the blue mould stain. It was very

pleasing to turn and sand so long as the tools were kept razor

sharp.

(click for close up view)

(click for close up view)

(Wed 7th Apr)

Nick Gosden writes :

Needing

to retain my grand children I decided to make some stair gates.

Needing

to retain my grand children I decided to make some stair gates.

Then thought it would be nice to make them with spindles to match the 100 year

old ones in the house.

I’m quite pleased with the result. The first pic shows my very very old lathe

with my homemade steady screwed to the bench.

The next

shows my spindle next to the 100 year old ones.

They were all hand turned. I know because I measured some and they are all

different.

Now to do another 10 and colour finish to match.

(Wed 7th Apr)

John Bolt has been sheltering the little people :

(click for close-up view)

(click for close-up view)

(Thu 25th Mar) Alan Brooks

reports on two of his pieces :

The first is a small piece of Robinia burr that came from

Paul’s place just prior to lockdown.

Bit of a challenge but finished up with it on a piece of branch wood as a

plinth.

(click for close-up view)

The second is a 'well dried out' piece of Yew (8" x 6"at

the widest point) with a few blemishes and a 6" test tube for buds/flower.

Finished as usual with Sanding Sealer and Renaissance wax.

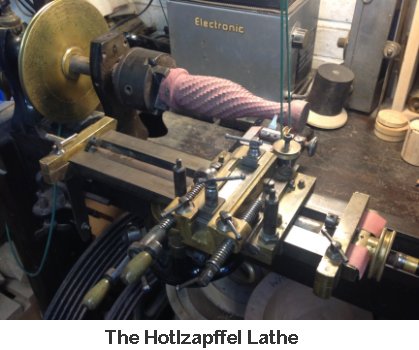

(Tue 23rd Mar)

Paul Reeves reports :

At last! I've finished my first 'proper'

ornamental piece on the Holtzapffel 984.

Burr Yew & Boxwood;

Walls 2-3mm; Height 225mm/9"; Diameter 130mm/5"; Weight

254g/9oz.

Thread chased by hand 16tpi.

(click for close-up view)

(Fri 19th Mar)

John Bolt having a 'Steampunk' moment :

If

anyone has some metal cogs spare I have some more ideas for using them. Thanks

in anticipation. JB.

(click for close-up view)

(Wed 10th Mar)

John Bolt preparing a Far Eastern Family Feast in Cedar :

(Sat 6th Mar)

Paul Reeves has been updating his production line :

I've devised a 'Small Log' mill to process the Cherry

I collected last month.

Below shows it set-up for the first cut :

(click for close-up view)

(Sun 21st Feb)

Another from John Bolt :

Shotgun cartridges caps decorating 2 boxes

designed to carry £1 coins.

(click for close-up view)

(Mon 14th Feb)

Terry Miles (via Vic Russell) reports

:

Just a heads up - Lidl have their pull-saw in the middle

aisle from Thursday 18th Feb. I use mine all the time.

<Lidl

Saw>

(Sun 14th Feb)

Paul Reeves has been milling planks again :

I've obtained some useful sized Cherry and Ginkgo

Biloba.

Ginkgo Biloba (aka The Maidenhair Tree) is an endangered species and the sole

survivor of its group after its nearest 'cousin' became extinct more than 200

million years ago. As such, it is often referred to as a 'Living Fossil.'

(see <Eden Project>)

It is also very rare to find in this size.

They should be available to Members once the moisture has dropped a bit.

(click for close up view)

(click for close up view)

(Thu 8th Feb)

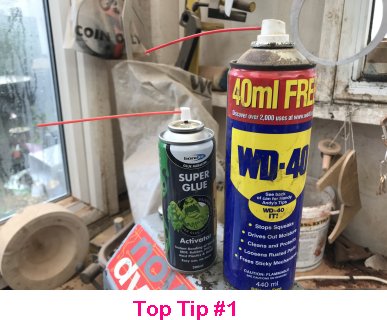

Top Tip

from John Bolt :

For precision spraying of my superglue

activator, I use the straw-like tube from a WD40 can.

(Fri

5th Feb) Two more contributions from David Patrick and Geoff Beddoe :

Two crush grinders made from Magnolia from the front garden

(cut late 2019).

An uncommon close grain hardwood that turns and finishes very nicely.

(Wed 3rd Feb)

Jerry Lewis writes :

Many may know about this already but

the Arboricultural Association has produced a free app called

'TMA Fungi' which has a fungi gallery

and tree list.

I mention this as I attempted to identify the fungus in the photograph of the

300 year old Oak taken by Paul Reeves below, <

HERE

>

My guess, and I am no expert at all, is that it is either dried

Smoky Polypore (Bjerkandera Adusta)

or Turkey Tail (Trametes

Versicolor).

Well that killed a few Covid lockdown hours!

(Wed 3rd Feb) Submission from

Peter Orr :

A Butterfly Urn/ Vase standing about 14” high and made in

three sections.

I used automotive spray paint and made hand drawn stencils for the decoration.

The handles were hand carved and although they resemble knuckle-dusters, they

are meant to be stylised butterfly’s wings.

(Tue

2nd Feb) Submission from John Bolt :

Bowl within a bowl - out of

Robinia

(click for close-up view)

(click for close-up view)

(Fri

29th Jan) Rick Patrick reports :

A friend asked me to turn some legs for a picnic

table where the table top was a floor of his horse drawn antique Wagonette and

the 30" legs were to be stored within the underside so that at a meeting place

with the occupants disembarked, the table could be re-assembled from parts of

the carriage.

For such an occasion, I thought a Cabriole leg would be more befitting than a

simple tapered round leg.

I decided that I would turn the 4 legs while each were at their initial centres

before starting to turn any at their off centres.

My thinking was that in the event of one leg ending up a smaller diameter than

the others (inevitably with my luck, it would be the last I turned), I would

still have the opportunity to turn the conflicting legs down to the smallest

size before progressing to the cabriole shaping.

Although Paul's Off-Centre Turning Demonstration talked about turning away the

'shadow' when using offset centres, I was concerned that over such a long

length, the diameter of the 'ankle' would be so much smaller than at the 'knee,'

it would make the leg look weak and wrong.

I opted instead to turning a gently changing 'shadow' which resulted from a

circle at the knee to a slightly smaller oval at the ankle, which preserved the

strength but still showed off the cabriole appearance. (click

the photo for a close up view)

Normally, turning a long thin spindle results in the piece vibrating such that

the gouge leaves corkscrew ripples along the sides. However, I discovered

that I didn't need a Lathe Steady because I used a 1/4" spindle gouge to turn

the wood away and the consequent small shavings seemed to work without any

vibration being created.

Despite the gouge helping to keep ripples at bay, the wood did have a tendency

to rip out in places so the last few millimetres had to be achieved using

abrasives with the lathe turning. Micrometer callipers were essential to

keep the ovals equal on all 4 legs and an electric sander with the lathe at rest

was the best way to reduce the over-sized dimension once the other had nearly

reached its required thickness.

I treated the foot soles with an Osmo waterproof varnish to prevent the feet

sucking moisture up the end-grain from any outdoor surface the picnic table was

set.

(Wed 27th Jan) Alan Brooks writes :

Below are images of a Beehive box

(5” x 3”) made from a piece of Robinia from Paul’s wood store collected prior to

lockdown. Honey dipper is from a Beech pen blank. Also dabbled for the first

time with Pyrography but need a lot more practice.

(Sun

24th Jan) John Bolt has been busy :

The

woods are ash, oak, birch, mahogany and ply.

(Thu

21st Jan) John Bolt writes :

Three alley cats idea seen

on Pinterest

(Fri

15th Jan) Alan Brooks writes :

Belated New Year wishes and hope you are still surviving. Just before the

latest lockdown I was able to pay Paul a visit to get a top up of blanks etc and

after a trial run with a piece of unknown timber have just completed the second

Puzzle ball/Sovereign Ball as demonstrated in the Woodturning magazine by Andy

Coates. The second ball was using London Plane from Paul’s supplies and whilst

filling his coffers was able to discuss different ways to approach the ball.

Will be using some of the Pear that I also got at the same time for the next

attempt. Also attached is a belated 4ft snowman from Leylandii and his little

helpers.

(click for close-up

view)

(click for close-up

view)

(Tue

12th Jan) David Patrick reports :

Geoff Beddoe and I find ourselves in the same bubble and

sharing a lathe. Over the last few weeks, the lockdown has given us the

opportunity to share ideas and do a little turning together, which the other

club members might find interesting :

Image 1 – Spice rack having an ash bowl, English oak spice pots with glass screw

on inserts and a Wenge handle.

Image 2 – Clock surround turned from an old Elm blank (looking a little like

swiss cheese) and base from African Blackwood. Barometer surround turned from

Sapele and also having an African Blackwood base.

Image 3 – Bowl turned from American Oak gifted by another member. Started out

with significant tear-out but rescued by Geoff to show off an very appealing

grain pattern.

(click for close-up

views)

(click for close-up

views)

(Fri

8th Jan)

Paul Reeves reports further :

All done; 300 years to cut & stack.

(Wed 6th Jan)

Paul Reeves reports :

Now THAT's what you call a plank!

32"x

78"

(click for close-up

view)

(click for close-up

view)

Oak slab table anyone?

(Thu

31st Dec) John Bolt reports :

Following Andrew Hall's

Smoking Snowman demo on line, you can place a incense cone inside the body and

the smoke will come out the mouth.

Happy New Year to all.

(Sun

20th Dec) Colin Jolly reports :

A Centrepiece for an oak table on Christmas Day.

(click for close-up

view)

(click for close-up

view)

(Sat

19th Dec) John Bolt reports :

I've pimped some sea

urchin shells with finials for the Xmas tree.

A Merry Xmas to you all and hopefully see you all sometime in 2021

(click for close-up

view)

(Sat

19th Dec) Trevor Elliott writes :

These are my Xmas candles. They almost look

like a pair when socially distanced!

Have a good Xmas if you can.

(click for close-up

view)

(click for close-up

view)

(Wed 16th Dec)

David Game writes :

It's party time so bring on the Clowns.

A Merry Christmas to everyone.

Let's hope we can get back to normal meetings in the New Year.

(Wed 16th Dec)

John Bolt has returned with tinted Xmas gnomes:

(click for close-up

view)

(Tue 9th

Dec)

Vic Russell writes :

Not

surprisingly I’ve seen lots of Snowmen on Facebook but thought these were pretty

good if any of you need inspiration.

I particularly like the bobble hats and carrot noses!

(click for close-up

view)

(Fri

4th Dec) Andy Olgilvie reports :

I don’t claim the

original thought on the masked snowman but as far as I’m aware, the original did

not carry the vital vaccine.

Not sure about the 3 week wait for a second dose!

(Thu 3rd Dec) John Bolt reveals what he has been turning during the latest lockdown. It is difficult to see what his hairy gnomes (disguised as Christmas tree ornaments) think of his walnut dish but the second gnome from the left looks like a hard case I wouldn't want to argue with.

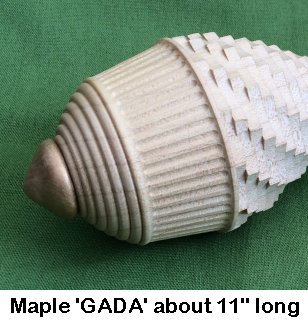

(Thu 12th Nov)

Andy Ogilvie has been busy!! :

As a result of my

continued efforts on the Holtzapffel I have joined the Society of Ornamental

Turners. Like CSW, they have competitions and this is my entry for the latest

one. The brief was to produce a ‘Gada’, which can either be taken to be a

ceremonial mace or a weapon used in training and combat.

It will be judged on its overall form and the technical skill demonstrated in

the decorative effects.

It is about 270mm long and made from maple.

(click for close-up

views)

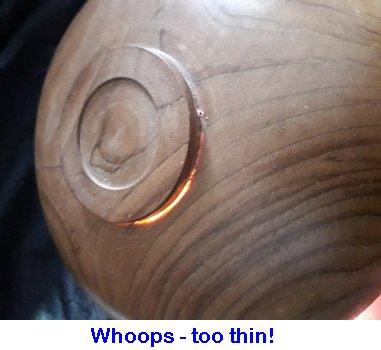

(Thu 5th Nov)

Ian Wright has suggested a section devoted to, what he describes, as a 'Whoops'

scenario.

He has shared two of his most memorable; an unintentional touch of

a gouge/tool rest and the bottom of a bowl getting transparently thin.

I must admit I've committed similar more than once.

Anybody else prepared to put there heads above the parapet?

Contributions from 'Anon' will be accepted and hopefully no one will send

examples in the name of somebody else!

(click for close-up

views)

(Wed 21st Oct)

Nick Gosden writes :

A close look

will reveal a lot of mistakes.

It was a massive challenge and learning curve.

In a couple of weeks I hope to have a friend try using it.

(Mon

12th Oct)

Paul Reeves reports upon what he did this weekend! :

This is a 300 yr old oak that fell over

during the storms in March.

The chain saw has a 42" bar full depth cutting and this is the thin end !!!!!

Only about 3 tons to go.

The root was completely dead and just snapped off.

It should have lifted the fence but didn't break anything.

(click for close-up

view)

(Back to Jerry Lewis & Fungi App)

(Fri 9th Oct)

Ian Wright writes :

A much played with but now neglected dusty old witch. She would have been

whizzed up about 40 years ago by a busy Dad from an oak offcut.

Come this Halloween, perhaps a turn would please a little one you know.

(click for close-up

view)

(click for close-up

view)

(Sat

3rd Oct) Andy Ogilvie has further Holtzapffel news to follow

Paul’s efforts :

A spiral basket weave pattern on a small vase (140mm

tall) in Purpleheart, finished with Danish Oil.

Careful depth calibration needed for each round of plunge cuts with a spinning

cutter.

The work was rotated using a headstock index for each cut and to achieve the

spiral effect.

(click for close-up

views)

Next, a 140mm dia bowl in Hornbeam decorated on the

Holtzapffel lathe, finished with sealer and wax, polished in part with a clean

shoe brush to get into the grooves.

The offset bowl was turned using an eccentric chuck which was also used for the

pattern in conjunction with the eccentric cutting frame.

The radius of the circles changed by only a few hundredths of an inch each time

- delicate work, lots of concentration!

(click for close-up

view)

(click for close-up

view)

(Thu 1st Oct)

Paul Reeves reports :

These coasters were turned on the Graduate lathe (over 50 yrs old) and

then decorated using the Holtzappfel lathe (just coming up to it's 200th

birthday). They are my first attempts at a pattern called Barleycorn and

as such are full of all the beginner's mistakes that I could manage.

The closest to the correct pattern is the centre of the left hand coaster. Nice

way to spend a couple of hours though.

(click for close-up

view)

(Thu 1st Oct)

Attilio has emailed to report that although he has been kept occupied

baking/making Italian dishes, he has found time to turn a thing or two.

A spiral vase in Lignum and a rollerball pen in Kiatt (South

African name for Manunga; a type of Padauk)

and a paddling of ducks

and a paddling of ducks

(click for close-up

views)

(Thu

17th

Sep) Trevor Elliott writes :

This project has been keeping me busy all

lockdown.

It'll be nice if we can ever get back to normal.

(Thu

10th

Sep) John Bolt has produced a

beech platter with iridescent paint having been applied then spun on the lathe.

(Sat

5th

Sep) Alan Brooks reports

again! :

This 'Bell Box' is taken from an

article in Woodturning Magazine by Ian Woodford as a symbol of ringing the bell

after a couple of friends beat cancer. This one is made from Bubinga (5” x 3”)

purchased from one of the club’s table top sales and finished with Renaissance wax.

Small

bell from 'The Range' fitted inside the lid but unfortunately doesn't ring as clearly as I

anticipated so tweaked it for the video here = <BellBox>

(Tue 1st

Sep) Alan Brooks reports :

These three boxes are approx. 4” x

½” and based on the work of Pat Carrol in the August

edition of woodturning magazine. The trinket boxes are made from Lime and then

engraved within the beads with a 3mm Dremel ball tool and then ebonised before

being painted with Pebeo studio acrylic HV iridescent paint. I found them very

time consuming in respect of what I normally turn and colouring isn’t my thing

so I probably won’t be turning too many of these!

(click for close-up

view)

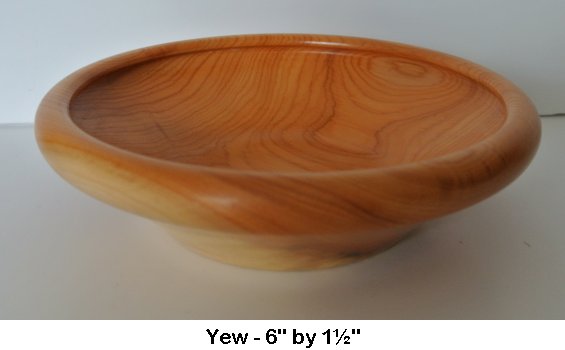

Some more items made from the timber

bought at the last club sale.

Natural edge bowl (8" x 1¼”) from a piece of Yew. Another Yew rolled edge bowl

(6” x 1½”). Finally a small bowl from a piece of Bay (4" x 1½”).

(Wed 19th Aug)

Andy Ogilvie writes :

Spalted Hornbeam pepper mill (190mm x 55mm dia) with Crushgrind mechanism

inside. Decorated on Holtzapffel lathe. Each cut made by a semi-circular cutter

spinning on its lateral axis, positioned using the 96 index. It was then

sealed, the depressions coloured using acrylic paints, lightly sanded and then

sprayed with semi-gloss lacquer.

(Fri 14th Aug)

David Game writes :

I bought several natural edge bowl blanks of American

Plane from Paul's recent wood sale.

This is the first one but unfortunately the bark came away.

It was finished with Danish Oil.

I'll have to see how the next one turns out.

(click for close-up

view)

With exam results out this week, I thought some 'Graduation Day' turnings would

be appropriate.

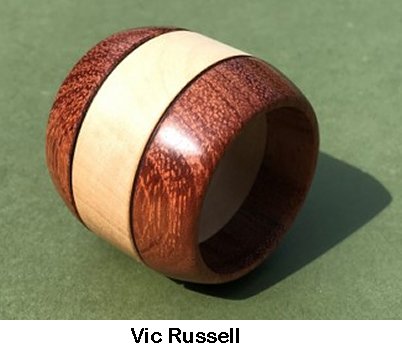

(Wed 12th Aug)

Vic Russell writes :

Something of a moot point really as we don’t even have any Napkins!

However in the spirit of joining in, I braved the shed to make this.

It was intended to be decorated from the start but the contrast between the

cross grain Sycamore and Bubinga looks so good I’m not sure I want to attempt

anything further.

We shall see when the heat in the workshop subsides!

Made using Mike Peace's

<

technique on YouTube >.

Now I have the jam chuck I’ll no doubt experiment further.

Meanwhile, I've entered this into Paul's Challenge,

(Mon 10th Aug)

David Hamilton's mirror work isn't in vain.

It's a 20" tall Vanity Mirror made in one of his favourite woods, Ash, with

reddish brown knobs of unknown timber hiding under his work bench! (click for larger)

(Thu 30th Jul) Alan Brooks has managed to transform some of his purchases from the wood sale within a few days. (click for larger)

(Tue 28th Jul)

Peter Orr has been mixing wood turning with some carving :-

As well as being a member of Christchurch

Woodturners, I am also a member of Alan Leagas’s Wood Craft Club at Arnewood,

Sway (previously Lymington Wood Carvers). The majority of the club are wood

carvers while just a few of us are turners. There had been a gentle humorous

urging that the turners should try some carving. My personal view was that

carving took forever whereas turning got much quicker results. However, during

the lockdown, I made a conscious effort to combine both disciplines. So I chose

subjects that could be turned in the early phase and then carved to complete the

project.

Hence the birth of the ice cream cone complete with chocolate flake.

I followed that with the basic turning of a bun, leaving

enough depth to carve a burger. I actually parted the bun about 2/3rd the way up

allowing me to carve burger and cheese slice on the lower portion and lettuce

and tomato on the top.

I painted both projects with acrylic paint and applied

acrylic varnish to cheese and burger and then the tomato. I used a Dremel to

remove wood quicker and then knives and chisels for more finesse.

Hope you enjoy this insight to carving from a wood turner.

We are always looking for new members at Alan’s and are gradually reopening with

temperatures monitored and distancing adhered to.

Please contact me (Peter Orr) on 07736 328121 if you are interested.

(Mon 27th Jul)

John Knowlton has completed a lockdown 'hollow form' project of beech & window

wood comprising of a total of 302 individual pieces! (Click for a closer view)

(Sun 26th Jul) Andy Ogilvie was fascinated with the peculiar grain he found on a pine plank.

(Mon 29th Jun)

Paul & Greta Reeves have written :

We hope that you have all tidied up your

workshops and are ready for your next quest!

How about having a go at turning an Acorn Box with either a push/pop on lid (or

for those of you with thread chasers) a screw-on.

30mm to 50mm suggested size, with or without the stalk.

Then attach a picture to <

HERE

> to put up on this website.

It's just a bit of fun; no competition or judging involved.

(Tue

23rd Jun) John Bolt has submitted 3 more owls :

(Tue

16th Jun) Rick Patrick writes :

The Club had received a commission request for 4 Belaying Pins for somebody's

flag staff, complete with yard arm & gaff. With no one forward to

volunteer their services after a few days, I agreed to have a go with some fruit

wood I had in stock. I subsequently found (what I believed to be) a Jarrah plank, which if it

was good enough for harbour piers and groynes, being left out

in all weathers on a flag staff should be no problem.

I've had a few

undistinguished attempts at copying turned pieces in the past so I knew how difficult it can

be to get 4 identical pins.

Unfortunately, with the first one I turned, I crabbed the tool rest into the top of the handle

so it became a little more oval ended than the rest but apart from that, I was pleased with the end result.

Each 'peg' was 25mm (±0.5) at the handle end with a slight taper to the bottom.

There was a similar slight taper with the handles themselves. I left them finished with 800 grit abrasive so that

he could treat them with

what he wanted.

I had an interesting dilemma in getting the commission to my punter.

We agreed to hand them over in the car park of Christchurch's Sainsburys in

those days of heightened Covid precautions.

I parked and watched for the car he had described and when it came, I opened up

my boot and laid the 'merchandise' out on the boot floor before retiring several

yards away. The punter duly inspected the goods, gave a nod of approval,

gathered them up, put them into his rucksack and left an envelope on the floor.

I had waited for him to get out of the way, quickly picked up the envelope, shut

the boot lid and drove off.

I started to think whether there was CCTV in that part of the car park; I

wondered what the Drug Squad would have made of it.

I had a few sleepless nights waiting for a knock on my front door in the early

hours of the morning!

(Thu 11th Jun) Vic Russell writes :

The question of whether you should take the tension off your Bandsaw Blades

after use comes up from time to time. It just has on Facebook so I did a quick

search. And found the following.

ALWAYS DE-TENSION YOUR BANDS

When you are done cutting for the day, take the tension off your blade. Band saw

blades, when warmed up from cutting, always stretch; and upon cooling shrink by

tens of thousandths of an inch each cooling period. Therefore, blades, when left

on the saw over tension themselves and leave the memory of the two wheels in the

steel of the band, which will cause cracking in the gullet. When you leave the

band on your saw under tension, not only do you distort the crown and flatten

out the tires (which makes them very hard), but you also place undue stress on

your bearings and shafts. Believe it or not; you can, and will damage your wheel

geometry sooner or later and considerably shorten bearing life. You are also

crushing your tires or V-belts.

It’s from here so I guess they should know!?

https://www.suffolkmachinery.com/index.html

Look under links, six rules of sawing then scroll down.

As a point of interest, I’ve always taken the tension off the blade after use as

it’s easily done on my bandsaw. I hope the information has been useful whether

or not you follow it!

(Tue

26th May) Vic Russell writes :

For those that didn’t get round to turning a miniature, you don’t have to use

small tools to turn them. It can be done with full size tools although I did use

a detail bit I made some time ago. The rest was done with a 3/8 spindle gouge.

(Sat 23rd May)

Paul Reeves has written :

The wood store hasn't been this empty

for years !

(Sat 23rd May)

Mark Codling has written :

Hi. Hope you are all okay in this stressful time ...

I’ve been quite busy. I got a load of beach, ash and oak recently and like to

turn green wood for Treen. I’d rather the bowls are used than sat on a shelf

(also I hate sanding)

Got to get that pole lathe sorted as I feel it’s slightly cheating turning Treen

on a powered lathe ...

Some had split but I think they improve with a bit of copper wire (very Japanese

in spirit).

(Mon 18th May) Vic Russell writes :

"I don’t have any wall space for these

types of tools so I used to keep stuff like this under the lathe. They used to

get covered in shavings and dust though so I finally ended up putting them in a

plastic tray. The tray soon got filled though and I’d “lose” stuff at the

bottom. I then remembered I had a tote tray that was bigger so I transferred all

the tools over. I still lost stuff though so then thought of adding a piece of

ply with some holes drilled in it for the tools to sit upright and this is

working out well."

(Mon 11th May)

John Bolt has submitted a home-made Sphere-turning jig made from Corian,

with 3 examples of the finished work (all 80mm diameter) :

(Thu 7th May)

Paul Reeves has written :

Below is a photo of a Prisoner

of War turned apple with tiny cups, plates and goblets etc. Turned in about

1946-7 and given to my grandparents as a thank you for their kindness. They

arranged for several prisoners to leave the camp at Weekley and visit families

in the Kettering , Northants area on Sundays so that they could attend church

and then go for lunch and tea. My Father corresponded with and visited one

man's family from near Stuttgart until he died in 2004. All the turning

was probably done with a sharp nail and the wood held in a hand drill. A two man

operation! They are made from boxwood (maybe from the Duke of Buccleugh's estate

nearby as some of the men worked on the estate growing food etc.)

(Wed

6th May) David Game has submitted something

for the kitchen and something to wave on

Thursday Nights to support the NHS.

(Thu 30th Apr)

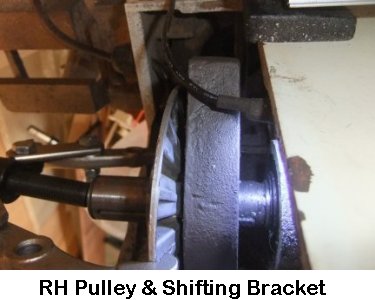

'Problems with my lathe' by Rick Patrick:

I had found the speed control lever on my Axminster SL900 lathe was becoming progressively more difficult to move.

While searching

Google for suggestions, I came across an Axminster 1998 publication stating that,

"The motor and drive shafts should be periodically checked for build up of wood dust. We recommend that you remove the belt cover every six months in order to vacuum dust from the area and to lubricate the pulley system ... after removing the belt."

Whoops! I've owned this lathe for over 10 years after buying it from another Member. I would be most surprised if the belt cover had ever been removed in the past 14 years!

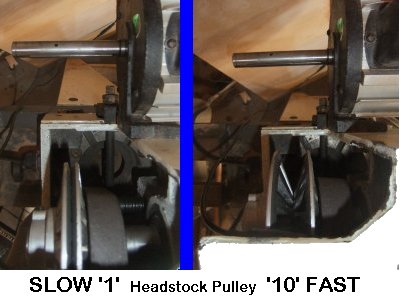

"Stop the machine on the slowest speed. Unplug power supply cable. Remove belt cover. Move speed selection lever to fast position. Remove the belt from the headstock shaft pulley, then slip the belt from the motor pulley. This pulley will now close together. If you wish to lubricate the headstock shaft pulley, now is the best time to do it. All that is required is to spray a PTFE dry lubricant BETWEEN the pulley halves. Move speed selection lever to “slow” position and spray the headstock shaft between the pulley and headstock casing."

Whoops again! That dust encrusted drive shaft had obviously absorbed moisture over the years and had corroded the metal

shaft such that the speed selector had now become stuck rigid it in its fast

position.

No alternative but to unscrew various circlips & grub screws and 'persuade' the individual halves of the pulleys off their slightly rusty shafts with a combination of a handmade U-shaped wedge of hardwood & an extractor.

Once I had worked out that the right hand pulley of the headstock was affixed to the shifting lever bracket so wouldn't comply with my misplaced encouragement of aforesaid wedge, the

spindles swiftly became clean & smooth with some wire wool and elbow grease.

Assembly was a straight retrace of the above (although I managed to miss a grub screw and had to back step when the speed control would only move towards faster).

"To fit a new belt you will need to prise open the motor pulley, either with your finger tips or with a pair of medium flat bladed screwdrivers held on opposite sides of the pulley."

Having easily got the belt over the headstock pulleys in their 'fast' position, I found the spring on the motor shaft too strong for my fingertips, so opted for the screwdrivers. I just needed the pulleys a little more apart so just wiggled the screwdriver to move down towards the shaft when there was a 'ding' from a stressed &

now broken pulley.

Oh

bugg

err, bother!

Fortunately, Axminster were able to supply a new pulley set via mail order so 3

days later I was back in business.

Some points to take away :

● There is a hole in the motor shaft for oil;

● Probably better to put the belt on the motor pulleys first as once in the

right position, the belt will be better able to prise open those pulleys before

passing over the headstock pulley set;

● I used a thin & wide wedge of boxwood to prise open pulleys after my mishap

with the screwdriver;

● Align the grub hole of the speed selector shaft with the speed number '6' for

getting the speed selecting lever in the right position of '1' SLOW and so

misses impeding the on/off cover;

(Thu 30th Apr)

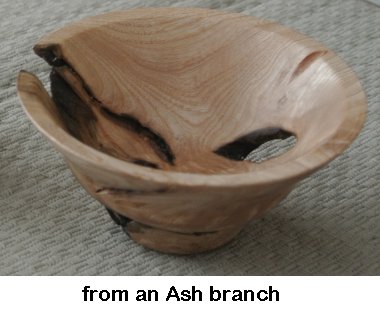

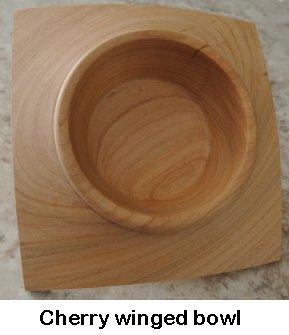

Alan Brooks has attached a couple of

images of small bowls made from originally discarded wood: A shallow Oak dish

and bowl from an Ash branch. Also tried a winged bowl from a piece of Cherry.

(Wed

29th Apr) John Bolt has submitted 2 pens made with kits from Stiles &

Bates and with acrylic infills.

(Fri 17th Apr)

John Bolt has written :

Examples of offset spindle turning .

Hope you all are staying well.

(Tue 21st Apr)

Ian Wright commented :

I like the 'im & 'er - very novel.

Regards the wine goblet - if, after a few, your glass looks like this, it's time

to stop drinking!

(Sat

11th Apr)

Paul Reeves has written :

This morning's project was Hornbeam, some

spalted, and a bit of spalted silver birch. Two nice natural edge vase blanks as

well.

Now it's just the sawdust to tidy up.

(Sat 11th Apr) A top tip from Terry Miles :

A tip from my good friend Vic Russell:

if you need something soft to secure an odd shaped piece while sanding or

finishing, a squash training ball is just the job. They can be had for a couple

of pounds from eBay, provided you don't mind the three week wait from China.

(Thu 9th Apr)

Paul Reeves has written :

This lawn edger was broken at work a few days

ago so I brought it home for the blade to be fitted with a new shaft. The ash

used for the original handle was very brittle and soft so I found a nice solid

piece of ash for the replacement. The shaft is 30" long and turned without a

steady. Finished with a coat of hard wax oil.

(Thu 9th Apr) John Bolt has added a new cocobola mini helmet to his collection.

Paul Reeves wrote on Saturday, 4th April 2020:

We were going to be stuck in all weekend with nothing

much to do so we have been cutting down trees today. Three self-sets that were

20' high growing in the border next to where Greta parks the TT. I meant

to take them out when they were 5' high!!!! 2 beech and an ash.

Also the big dead oak with the seat round it is no longer vertical with some to

be milled tomorrow. I don't think it would have been too long before it fell

over anyway. Let's hope that the Duster will haul it out of the hole.

(Looks like fresh supplies for the Club Wood

Sale in a year or two)

Vic Russell writes :

"Not

Woodturning I know but as some may be aware, there’s a fad on FaceBook at the

moment for making Squirrel tables from scraps of wood!

This is my attempt."

(I remember watching TV programmes with squirrels working with tight ropes, hoop jumping and pulling sticks out of a maze to release some food. How's Vic's picnic table going to test them. Oh --- hang on a minute. How high is this table off the ground?)

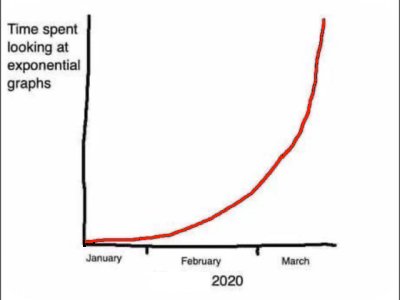

For info :

Below is a graph illustrating the time we spend looking at exponential graphs

(Terry Miles)

Beware...

Your webmaster has just received the following attachment in an email sent to

the CSW's Coronavirus email address and slipped through my anti-virus software!

Please view at least 2 metres from the screen, stay at home & stay safe.

As we started making our own Pizza’s a while back, I bought a Pizza Peel for

getting them into and out of the oven. The metal blade was ok but the

rectangular section wooden handle was useless so I turned this today. A simple

job for what is fast becoming an essential kitchen tool!

Some Members might remember the laminated stool that I made

for my granddaughter and entered into the 'spindle and faceplate' turned

competition. I had some offcuts left over from the legs and made a handle

from them.

The keyless chuck was only £6 or so from China but works really well.

This bowl was rough turned from a chunk of Plane last June

and finished last week with a decorative band using a mix of beading, pyrography

and spirit pens to achieve the result. Additionally, I've clearly got more

time on my hands than I care to admit so have a go at this Horizontal Crossword

with answers all relevant to woodturning.

Regards, Andy Ogilvie. <

CROSSWORD

>

(Send completed crossword back to the Webmaster and

I'll keep a score of who has succeeded or give you a clue if you went wrong)

More podlets from John Bolt in black, white & natural.

Following Paul's demo on offset spindle turning, I enclose

pictures of a candle holder which I started a year or so ago and just completed

as a rounded triangular spindle type.

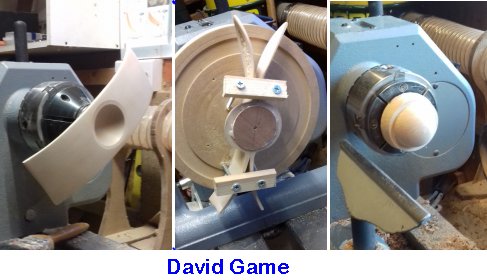

I also made a rabbit box this month in time for Easter. David Game.

(Nice to see how you did it - RP)

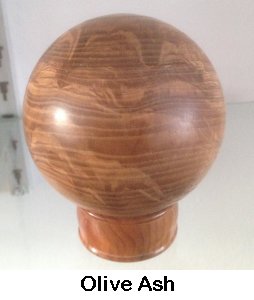

I turned this on my sphere jig the other day.

5” diameter in sycamore and a couple of other hardwoods, one possibly walnut.

Lego Carpenter for scale!

... also in the picture, a new cup chuck I made to fit my OneWay live

centre to support the ball when sanding.

Vic.